From the mighty pines and spruce of British Columbia to the tiny crill from wood chip particles – Canfor Pulp’s Innovation director Paul Watson and scientist Paul Bichot tell TWM about the intense and on-going focus on quality control.

These are important properties for tissue makers, especially when tissue is produced using wet shaping on the tissue paper machine or employing elaborate embossing in converting that involve different patterns and depths.

In these bulk and absorption generating processes, long and flexible fibres are desirable in order to maintain the strength of the tissue sheet. The amount of long fibre can be minimised as Canfor Pulp NBSK delivers a high strength with minimal refining. As a result, it is possible to use more hardwood in the tissue furnish and reduce cost while having a positive impact on tissue properties such as bulk (or caliper) and softness.

Technical “know how” and its constant application is a vital requirement to stay competitive. Canfor Pulp Innovation uses an “open innovation” platform with a number of partners (including AFT FineBar, Voith, Buckman, Pulp Eye, the University of British Columbia, FP Innovations and research company Innventia). The research areas comprise pulp preparation and refining, pulp quality and control, tissue quality and processing efficiencies as a function of fibre input and internal kraft pulp process optimisation.

We support tissue customers with analysis and testing in our facilities as well as in their tissue mills. Often this involves looking at final tissue quality in relation to the furnish and furnish preparation, as well as how it affects process efficiencies. In order to simulate the response of refiners that are actually used in tissue mills, refining at Canfor Pulp Innovations is done on a pilot disk refiner rather than the laboratory PFI mill which, owing to its extremely high energy and low intensity fibre treatment, does not generally deliver results that are representative of industrial applications.

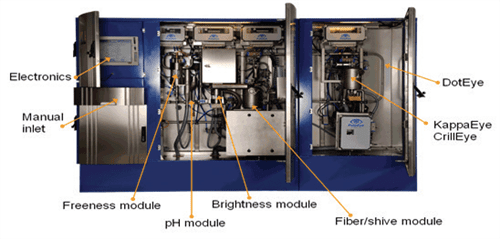

In a study into online pulp quality monitoring systems in the Mihari (Japanese for “watchguard”) project, the key technologies covering the pulp making process are the PulpEye developed by PulpEyeAB and the Quality Vision System developed by Metso. The objective of these systems is to enable better control of the pulping process in order to improve pulp quality and to supply more precise pulp quality data to the customers on a per shipment basis.

It is common practice for pulp suppliers to base the pulp quality factors and averages for longer periods of time, which are often not representative of delivered quality. The pulp lot that is received by a customer may deviate from the long term average as often the pulp quality of a lot is not considered by the customer, and so he will adjust process conditions after the fact. In preparation for the delivery of per shipment pulp quality data on-line a smart phone with a scan app can now be used to access the average pulp quality over a three month period.

Fibre properties on the level of the individual fibres are time consuming and expensive to measure, even in a laboratory setting. Canfor Pulp Innovation has installed a PulpEye system dedicated to the development of the next generation of fibre properties measurement. Two measurements that we will soon employ in our kraft mill online measurement system are the measurement of crill and the measurement of fibre wall thickness (FWT).

The crill measurement was previously developed by Innventia and Pulp Eye. “Crill” is described as very thin particles (fibrils) that are partially or completely loosened from the fibres and are about 100 times thinner than the fibres. The portion of crill in a low consistency refined pulp, commonly used in tissue making, is small. By weight it can be only 1%, however it has a disproportionate positive effect on fibre bonding and paper strength.

The measurement, performed with the OptoCrill module and software is based on the comparison of two optically measured surface areas, using light of different wave lengths. The total surface area of fibres and crill is measured with UV while the total surface area of the fibres only is measured with IR. This is a direct measurement, no image analysis is performed, so the measurement is extremely fast. The crill ratio can be expressed as the surface area of fibres and crill divided by the surface area of the fibres. The OptoCrill is integrated in the Pulp-Eye system and is being used by Canfor Pulp to assist with the development of on-line tensile strength predictions.

|

|

|

State-of-the-art in pulp analyser and control technology

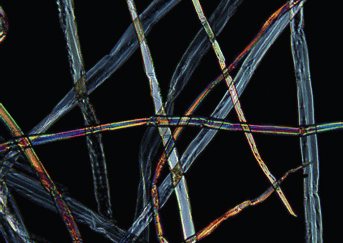

In close collaboration with partners PulpEyeAB and FPInnovations, we have recently developed an on-line fibre wall thickness measurement module. The tissue maker familiar with coarseness knows that it depends on the cross sectional fibre area, the fibre width and the fibre wall thickness.

The fibre wall thickness gives more information about a pulp than just a coarseness value, in measurement with various pulps a good repeatability and separation was found. Importantly, unlike the coarseness measurement which is an average value, the fibre wall thickness module delivers wall thickness distribution data.

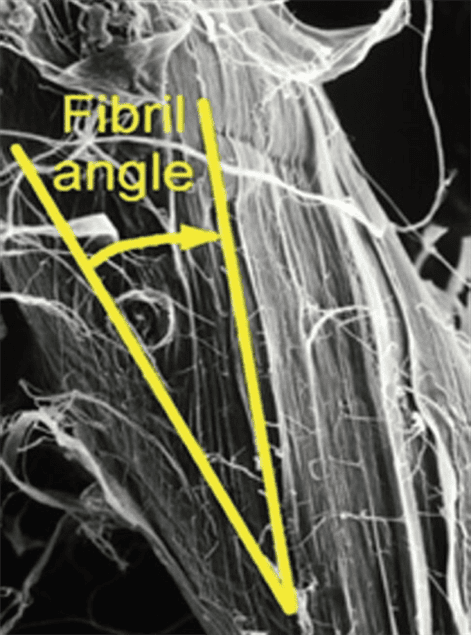

Of particular interest to the tissue maker are the differences in the wall thicknesses of various hardwood pulps, even between fibres of the same species like eucalyptus. Thinner walled finer and low angle fibril angle fibres make a stronger sheet with a smoother surface, and these are desirable properties for tissue producers.

Fibril angle

The basic concept of the fibre wall thickness measurement is based on the double refraction in anisotropic materials, whereby the colour correlates with fibre wall thickness and fibril angle.

The mapping from colour to fibre wall thickness and fibril angle is defined by a complex non-linear function, for which solutions were found. The easily accessible and more precise pulp quality data will help tissue producers determine and set process conditions for the desired quality tissue base sheet.