Essity’s drive towards a “truly circular society” has opened up another stream of raw material resource linking circularity and proximity. Donato Giorgio, President, Global Supply Chain, Essity, talks to Tissue World Magazine Senior Editor Helen Morris about his vision.

Wheat straw, food and beverage cartons, banana plantation residue, miscanthus or bagasse, waterless production … recycled paper cups from fast-food restaurants. A variety of raw materials are now being used or piloted to manufacture tissue products on a worldwide scale, suggesting a turning point for the ambitions of the global T&T industry that can now increasingly seek out native and locally sourced materials that surround existing tissue plants.

One company leading such innovation stakes is Essity, which just over two years ago started up its Mannheim, Germany-based plant, where it takes native fibre (wheat straw) from agricultural by-products surrounding the mill to make tissue products. At the time, Donato Giorgio, President, Global Supply Chain, Essity, detailed to TWM how the raw material was “a sustainable alternative pulp”, and that the process was expected to reduce the use of water, energy, and chemicals, with the by-product of the integrated pulping process refined and used as a substitute for oil-based chemicals.

The final tissue product is now marketed in Germany under Essity’s Zewa brand, encapsulating Giorgio’s vision of using “local and native” raw materials from the doorstep of production facilities. “A truly circular society”, he adds. At the time of the interview, what gave the process wider significance was the potential for rolling the model out elsewhere. Other native by-products located close to production sites around the world could be involved.

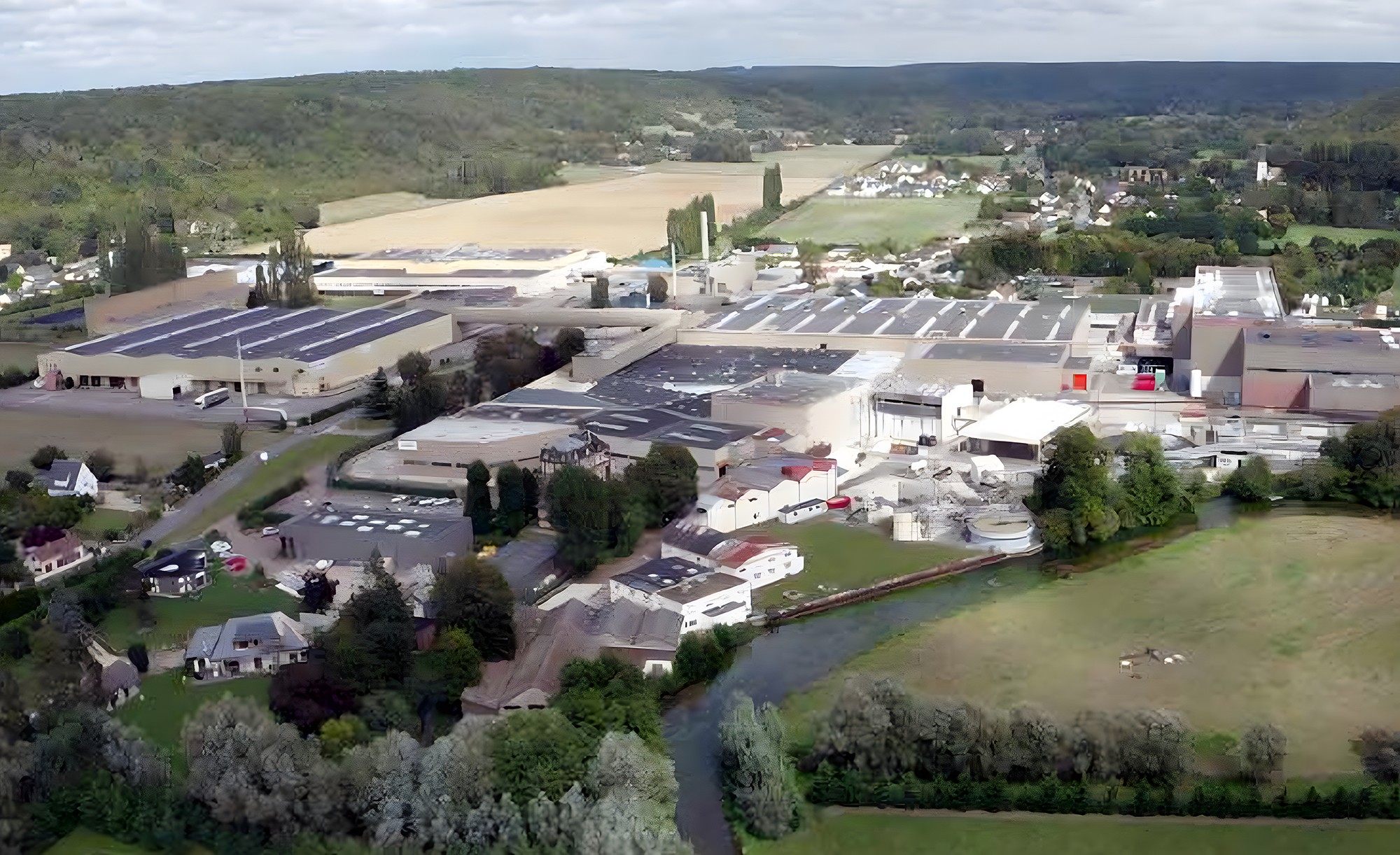

Now in 2023, and Giorgio’s vision for a circular society is stronger still. In October, Essity announced another world first – this time in France, where it had inaugurated its Hondouville facility. The site takes over 60% of all of France’s collected, sorted, and recycled food and beverage cartons and turns it into tissue products that are sold under the Tork brand. “The production of Professional Hygiene tissue products where the raw material is used food and milk packaging is a world first,” he says. “We have made something very beautiful.”

The facility currently recycles 25,000tpy, and its expansion into recycling food and beverage cartons has increased its recycling capacity by 40%, as well as enabling the recycling of almost all packaging materials – including plastic and aluminium.

“We are very proud of how we have evolved the Hondouville production plant into the end-to-end circular economy we have today,” he says. “Initially, we implemented the Toyota total employee involvement concept at the site, which adapts the core Toyota principle of kaizen – constant improvement. The concept of food carton box recycling was interesting for us, and we wanted to see how we could evolve and improve its use in our industry. We then invested substantial resources and R&D, technology, engineering, as well as manufacturing an eco-system which involves our suppliers across the supply chain in order to magnify and leverage full potential. As a result, Hondouville is now one of the world leading factories for sustainability in Professional Hygiene. It has become one of the best performing factories, and here we are with this great product.”

Giorgio says the site is “truly unique, because it is the full eco system”. Yet across Essity, he adds the business prioritises innovation. The company now has similar recycling initiatives in Germany, the Netherlands, and most recently in Ecuador, where the business is collaborating with McDonald’s and ReciVeci – an initiative that helps promote inclusive recycling and the circular economy across Latin America – to recycle paper cups from fast-food restaurants. Essity also became the first in the industry to produce tissue in a CO2 emission-free production process by using renewable hydrogen at its production facility in Mainz-Kostheim, Germany. The plant uses hydrogen as a final building block to replace natural gas in the hood dryer of the process. And its Lilla Edet mill in Sweden, again with the Tork brand, is “the first fossil-free tissue mill.”

“Innovation is a constant element for us across the business”, he says. “And if we look upstream in the process, a few months ago we announced substantial investments with our partnership with Voith to develop a waterless process for the future. We are progressing very well here; it is a breakthrough for the world. In the end, we are making access hygiene more available, more accessible. We are making it cheaper, better, and available to a larger part of the population in line with our purpose to remove the barrier to wellbeing. It makes us unique in the world.”

Back at Hondouville, Giorgio emphasises that what makes the plant truly unique is that it “encapsulates the full eco system”. He says: “There are other companies that are recycling with Tetra Pack carton packages, but what we are doing is maximising the capacity across the whole chain. We are recycling close to 100% full fibre, and we are the only one in the world using Professional Hygiene for strategical products. So it is the full mix in the end that makes it unique.”

Is the French market especially particular to this type of product? He says this French plant is “the first and only in the Professional Hygiene world with fibres from food carton. It was important the Tork brand position itself here for a circular economy, for advantages in sustainability whilst also bringing the advantage of the product. There is huge demand for these types of activities.”

He likens the innovation to Tesla, the American multinational automotive and clean energy company which designs and manufactures electric vehicles: “I see Essity as being better than Tesla in contributing to the world because of what we are doing to work towards circularity, CO2 reduction, for removing the barrier to wellbeing – which really means moving the barrier to hygiene products. It’s unique.”

At Hondouville, 25,000tpy are currently recycled, which is 60% of all the collected, sorted recycled food and beverage cartons in France. The site’s capacity is up to 60,000tpy, so more capacity can be added in the future. “It could be an option to increase, from a technological point of view we can. We have to study if there is a possibility to have the material, because we need an equilibrium between the CO2 and the circularity of getting the material and recycling it, or if you generate more CO2 in transporting it.”

In line with this, he adds that another unique element for the worldwide Professional Hygiene market is the company’s Tork PaperCycle, which it has rolled out at its Lilla Edet and Mainz-Kostheim plants. Tork PaperCircle, he says, is a world first recycling service for paper hand towels and means a business can go circular by collecting and recycling used paper hand towels which are then created into new tissue products. “It’s turning waste into a resource, and it is something that we continue to invest in. It’s the best of the best, you don’t have any fibre going to waste.”

A holistic assessment of all the issues is the key to circularity: “When people ask me which is the most sustainable, it depends on the type of customer and consumer you are selling to, and where you are located and what kind of material is available nearby. The winning concept is that of circularity and proximity. It’s about creating a balance between recycling with a food carton, recycled with Tork paper, recycling your own product, or using virgin paper when it makes sense, or using normal recycled fibre when it makes sense.”

He cites the Mannheim plant as a good example, a prototype of what he hopes will be “the first of many such facilities that will change the future of tissue.”

Close resource proximity is vital: “Today we are seeing geographical areas that may have supply chain disruption because of Covid, because of wars. So the closer proximity you have to reduce the impact of the natural resources, the better it is. This is our concept, and we try to have it for all our products and all future Essity sites. That serves customer and consumer in a better way. And what I believe strongly – and this is why I say Essity compares with Tesla – is that by serving the consumer and the customer with something that is truly circular, that reduces the footprint on the planet, and at the same time gives a more affordable and better product. This is the key for the future economy.”

He reiterates the aim of removing the barrier to wellbeing around the world: “We are the hygiene product. The biggest motivation we have is that only 45% of the world’s population has access to hygiene products. That means 55% does not have access, because you cannot currently produce in proximity in every region of the world because this industry is too heavily capital intense, because our supply chain is using raw material that comes only from some specific parts of the world. We are working to fix this problem.”

His dream, one day, is for Africa: “I want to have a facility, with solar panels, using all kinds of available raw materials local to the production site, making hygiene products for the local population. The tissue industry needs to become smaller, more local, and cheaper. In this way, you have a better footprint, and you remove the barrier to wellbeing around the world. But if we remove the barrier to well-being and sell something that costs double, even 10% more, we are not removing that barrier.”

In many parts of the world, eliminating water from the tissue manufacturing process will be vital to “disrupting the paper making process”. In March, Essity disclosed its pilot R&D machine in partnership with Voith, which aims to develop a new tissue making process that will reduce energy and CO2 emissions while cutting water consumption by up to 95%. “I can’t disclose too much at this time, just that we are looking at developing a new process without water,” he says. The new concept will “revolutionise and rethink tissue manufacturing,” and a pilot phase will be launched later this year before being implemented industrially. Compared to conventional paper making processes, this process could enable CO2-neutral tissue production, reduce freshwater consumption by 95%, and lower energy consumption by up to 40%.

“We are currently creating paper how the Egyptians were doing so 3,000 years ago, in exactly the same way,” Giorgio adds. “Forming the sheet with water. We don’t yet know a different way of doing it and we need to think of a different way to make the fibre. This is a unique thing in a constellation of big activities that will change the world. If you take the iPhone, one of the biggest inventions of the world, the iPhone is putting together a lot of things that existed before in a different way. This is our ambition, to look at doing what we do in a different way.”

All of which are impressive steps towards the company’s aim of achieving net zero emissions by 2050. Hondouville offers a blueprint for circularity that will be rolled out further afield and assimilated into the local environment: “We are the number one in Latin America, for example, and in central America we have intense use of recycled fibre. So this could be a very interesting application for there.”

While at Mannheim, the “beauty of it is the agricultural waste available that is close to the plant, which makes it one of the most successful circular economies.” He adds: “Out of that wheat straw, we then have a unique local process that sends the pulp directly to the paper machine, and 50% of the yield makes our innovative product. And from that bio-based material we have already produced bio-packaging. So the beauty of the concept is that wherever you are, you see what kind of aquicultural available waste product is available locally, so it’s not competing with the food industry, and then you can use miscanthus, or bagasse, or in central America you can use the residues of banana plantations.

“You can have a facility where you place one ton of agricultural waste, locally taken, and then with half of it you make the hygiene product, and with the other half you make the packaging and all the other things you need to sell it. A truly circular society.”