In January, Infinity Machine & Engineering Corp., headquartered in De Pere, Wisconsin, US, announced it had further expanded its roster of automated machinery to cover the end of the production line by launching its latest palletiser, the R10SW. Here, Gregory Sense, Marketing Coordinator, details its qualities. A TWM report.

It is no secret that in recent decades manufacturers have pivoted toward automating the production process at a rapid pace. And as the cost of labour has steadily increased, there is no indication this shift towards automation will slow down anytime soon.

Tissue converters have been especially proactive in implementing automation into their production, as nearly every step of the converting process can and has been automated. In 2004, Infinity Machine & Engineering Corp. was founded in response to the surge in automated tissue converting lines and has led the charge in automating the tissue packaging process ever since.

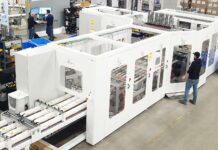

Already boasting the most comprehensive roster of automated packaging machinery in the industry, Infinity is further expanding its roster of automated machinery to cover the end of the production line with the R10SW palletiser. Responding to consumer demand, the R10SW palletiser can be integrated with Infinity packaging lines, enabling Infinity machinery to automate every step of the tissue production process after the log saw.

A key aspect of the R10SW palletiser is its modularity. The R10SW is made up of modular palletiser sections that can be arranged into countless different layouts to accommodate production requirements, as well as facility limitations. The flexibility created by these palletiser sections make it perfect for a multitude of product lines, from single product, to large-scale, multi-line operations.

The palletiser segments offered by Infinity include automatic slip sheet placement, integrated labelling, and fully automatic, fully servo stretch wrapping. All designed to provide extreme efficiency and flexibility in a minimal amount of space.

The R10SW palletiser comes equipped with an articulated robot arm from FANUC, one of the world’s largest industrial robot manufacturers. The R10SW’s FANUC articulated robot arm is capable of quick cycle times and robust performance. The development of the R10SW palletiser has led to Infinity becoming an official “FANUC Authorised System Integrator”.

Versatility and robust performance capabilities are built into the design of the R10SW. Vacuum or servo gripper end effectors can be equipped on the palletiser, allowing for high-speed stacking on a wide range of products, including cases, bundles and DRP.

One focus for Infinity engineers in the design of the R10SW was prioritising operator convenience and safety. This resulted in a machine that features multiple safety zones separated by access gates, allowing for safe observation of production. Access to hard-to-reach areas of the machine has also been improved, culminating in a palletiser that is as safe as it is accessible.

Operators of the R10SW are given total control from the machine’s HMI. Convenient access to production information such as wrap status, load height, and slip sheet quantity allows for possible adjustments in production to be identified and made immediately from the HMI.

As tissue converters throughout the world continue to embrace automation, flexibility is as essential in the production’s end-of-line as it is in the converting and packaging process. The R10SW brings Infinity’s signature innovative engineering and robust build quality to the world of palletising solutions, making the production end-of-line safer, smarter, and as flexible as the rest of your line.

This article was written for Tissue World Magazine by Gregory Sense, Marketing Coordinator, Infinity Machine & Engineering Corp.