Case study: Josh Goulet, Account Manager, Edson, discusses designing and installing automation into end-of-line packaging for diaper manufacturers. A TWM report.

There was a time not that long ago that many end-user paper customers would manage all aspects of a new packaging line integration. They would map out expansion plans within their facility, research available packaging options, evaluate different packaging suppliers, compare quotes – in other words, do all the heavy lifting themselves in addition to their regular duties.

These types of expansion scenarios are becoming less common however, as trimmed-down staffs and dwindling tribal knowledge relating to managing projects of this scope are leading some companies to look for alternatives. Reduced staffing is pushing companies to streamline the specification process by having one supplier assume control of a project from initiation through completion. This trend relies on the expertise of the partnering supplier to work with other vendors to research and recommend a total line solution.

This shift has created an opportunity for suppliers to assume the dual roles of project management and integrator for full end-of-line packing applications. Some RFPs are directing a supplier to essentially take ownership of the whole line from the time their products are in the primary package all the way to the pallet.

That can be a big endeavor to undertake but, we are seeing more requests like this, and not just from small to mid-size companies; large Fortune 500 companies have begun pushing project management duties onto suppliers as well.

ProMach’s business model has evolved. If you call us with a project involving a case packer, you also need the labeling, marking, coding, weighing, conveying and palletising equipment that comes both before and after the case packing machinery. While Edson specialises in case packers, our business can attend to the rest of a packaging line. The advantages of this is that we can specify all the equipment needed for a diaper packaging line, and do so in a streamlined process where all facets of the project are unified under one roof.

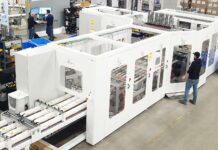

An entire case packing line installation was completed recently for a major North American diaper manufacturer in which two ProMach brands, Edson and Zarpac, managed the project from start to finish. The customer was bringing to life a fully automated packaging line and successful installation that was not only turnkey, but, managed by one central point of contact.

For years, the diaper manufacturer followed the practice of hand packing all its diapers and it was not looking to add more automation to it packing process. For larger orders, leadership would schedule 20 or more temporary workers to handle shipments; other days, a staff of 10 could handle packing duties. The drive to automate was in part due to Covid-19 and the regulations outlining distancing to employees, but the company was also growing and needed to upgrade its packing capabilities to meet increased orders without having to hire temporary workers.

While the initial thought was to automate case packing and palletising, Edson identified areas where additional efficiencies could be gained during the exploratory process by auditing the customer’s entire packaging and packing lines. When Zarpac was brought in, overall equipment effectiveness optimised line design and turnkey packaging systems.

Edson and Zarpac completed an on-site visit to the diaper manufacturer where they laser-scanned the facility to create a 3D model of the layout. From there, they began designing the lines by placing equipment such as the conveyors, metal detectors, weight checkers, case packers, and palletisers, to ensure adequate product flow within the facility. Additionally, their plans called for the expansion of 11 total lines, so future installations were also accounted for. The first part of this project included two pack lines.

While the conveyance was supplied by a non-ProMach company, ProMach integrated that system with the entire line. Edson can integrate with other brands, especially if customers have a pre-existing packaging line or relationship with other brands but is looking to upgrade just their casepacker, or if another brand may be a better solution for the project.

For the factory acceptance test, Edson and Zarpac hosted it remotely through video conferencing, machine videos of operation, speed runs, induced failures, individual machine assemblies, as well as supporting test documentation to provide the customer with full action validations. With ongoing travel restrictions, the customer was able to express any questions or concerns it had before receiving its machines.

When all the pack lines are fully functional they will be running at around 21 cases a minute. If future production increases, the pack lines and case packers have the flexibility to increase speed as well. Some diaper manufacturers are packing 30 cases per minute; those speeds are likely to rise to 40 or more cases per minute in the coming years due to market demands. It is important that not only the case packer can handle those speeds but also that all machinery on the line is up to the task. Flexibility of equipment to meet changing market environments for diapers and other converted paper products is key to staying ahead of the competition.

This article was written for TWM by Josh Goulet, Account Manager, Edson.