Körber Tissue has integrated the latest artificial intelligence to provide the most effective solution for primary packaging quality inspection. Nicolò Squarzoni, Product Manager – Packaging and Digital, discusses how convolutional neural networks work, and why they represent the most effective solution for packaging quality visual inspections. A TWM report.

For some years the consumer economy has started to adopt and appreciate the power of artificial intelligence (AI).

It started as a foundational technology in speech, text, and image recognition in mobile phones, progressively expanding to many other applications such as medical diagnostics, internet security, decision making, and now this same technology has matured to be applied to quality inspection and other judgment-based uses in the manufacturing environment. Due to computational limitations of CPUs, AI was not able to be adopted earlier, and now that this technological gap has been filled several manufacturing processes can benefit from a new immense power.

Körber Tissue has invested a consistent part of its R&D budget in the application of AI to develop solutions for tissue manufacturers.

The first result is a system for quality packaging inspection that was launched a year ago under the name of Sam Pack. This system learns how a good sample looks, and is then able to recognise samples different from it given a specific tolerance. With the same approach, Sam Pack is also able to learn to recognise specific defects of packs such as print misalignments, side sealing defects, etc.

The core of this technology is the application of convolutional neural networks and deep learning techniques to allow an accurate and at the same time simple way to inspect packaging quality during production. This article will explain how this technology works and why it brings consistent advantages compared to both human inspection and traditional vision systems based on rule algorithms.

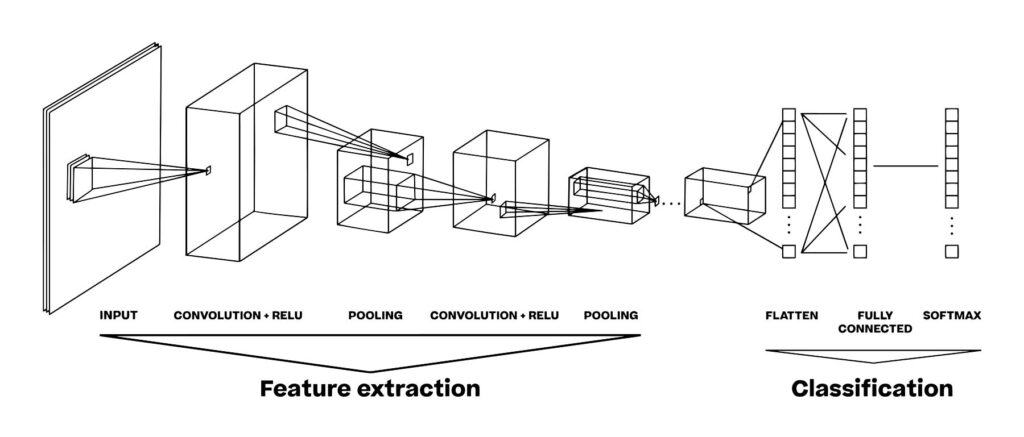

The concept behind a convolutional neural network is to mimic the neuron network responsible for image processing and decision-making in a human brain. The network receives as input the image to process, and it is divided into several layers, each one with specific functions. The first group comprises convolutional layers and is responsible for drastically reducing the amount of information stored in the pixels composing the image, leaving only the useful details that actually help to distinguish the input image and reducing the amount of data to process. This is called feature extraction.

The second group comprises fully connected layers, and they are responsible for representing in the best possible way the reference image and to decide how similar a random input image is compared to the reference. This process is called classification. The key of this architecture, which makes it incredibly flexible, is that each layer contains a defined number of parameters that need to be set in order for the network to extract the right details from the image, to correctly represent the reference image and consequentially to correctly decide if a random image is similar or not to the reference.

The process to set this parameters is called deep learning. It consists in feeding the network with a set of images representing the reference, which in case of packaging quality inspection are images of good samples, and specific algorithms can recursively set the parameters to get to a final configuration that performs feature extraction and classification in the best possible way.

This learning process can be done every time the reference image needs to change, for example changing from one pack format to another, and it just needs to scan a few good samples. Then the software updates the network automatically.

It appears very clear then that this technology offers great advantages compared to traditional vision systems. They are based on rule algorithms, and this means that for each detail of the image to recognise, a specific rule needs to be coded. This solution can be effective in the case of simple images with very low variability, but in the opposite case it’s necessary that a huge number of lines of codes require high costs to create, maintain and modify, other that high coding skills. Also, for complex images, the performance of convolutional neural networks is consistently higher and it is possible to customise the decision tolerance of the network in evaluating the similarity of the image of a random pack with the reference. Comparing Sam Pack with the traditional human inspection several advantages can also be recognised, such as the stability of the inspection 24/7, the reliability and moreover the speed.

In conclusion it can be observed that convolutional neural networks have been designed to feature the advantages of both human inspection, for accuracy and flexibility, and automated inspection, for reliability, stability and speed, representing the current state of the art for visual quality inspection.

This article was written for TWM by Nicolò Squarzoni, Product Manager – Packaging and Digital, Körber Tissue.