A significant increase in the on-line purchase of tissue products, brought about by the pandemic, is the latest trend for the global packaging market. Nicolò Squarzoni, Product Manager at Körber Business Area Tissue, discusses the company’s latest machinery launch

In 2020, the Covid-19 pandemic led to a significant increase in growth across all tissue categories, excluding napkins. Furthermore, during 2021 – 2026 the global tissue paper market is expected to grow at a CAGR of 6.45%. In this scenario, although 90% of tissue sales will still occur in-store, growth of the e-commerce channel will top 15% for almost all tissue and towel categories. Tissue is projected to be one of the fastest growing e-commerce product categories. These developments will also offer up opportunity for producers to propose sustainable packaging options to the market such as kraft paper, bioplastic and recycled LPDE.

Such increases in demands in both e-commerce and sustainability have been caused by the pandemic and are trends that will drive the tissue market in the coming years.

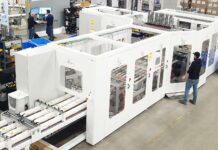

In response, Körber Business Area Tissue has launched the Casmatic Zephyrus, which represents a new era of packaging in the tissue industry due to a patented application of delta robots’ technology.

The Casmatic Zephyrus is able to respond to both e-commerce and sustainability challenges with an integrated and highly automated solution. Modularity and flexibility have been the key drivers during the entire development stage and as a result this solution features four different modules: infeed, box former, pick and place and outfeed.

The box former module picks the flat boxes from the stack, applies glue and forms the boxes. The infeed module receives the tissue products from the upstream machines and separates them according to the selected pack format. In the pick and place module the delta robots pick the grouped products and fill the boxes, which are then glued and sealed in the outfeed module.

Casmatic Zephyrus offers high flexibility in production thanks to the possibility of increasing its production capacity by adding extra box former modules and extra pick and place modules for a speed range of 45 – 180 boxes per minute. It can be integrated into an existing packaging line between the log saw and standard packaging machines with the possibility of producing in three different modes:

• Full production: tissue products are all packed by Casmatic Zephyrus.

• Mixed production: tissue products are packed by both Casmatic Zephyrus and standard packaging machines.

• Bypass: Casmatic Zephyrus let pass through all the products which are then packed by the standard machines only.

The customer can then produce additional and sustainable pack formats made from cardboard and microwaved carton, with the possibility to expand its business with minimum impact on the existing layout.

The delta robots ensure maximum flexibility and precision in product handling, providing the ability to package different products at the same time and even two different pack formats at the same time.

The modular design guarantees fast installation and commissioning while the modern frame design with full plexiglass doors guarantees high visibility of all mechanical parts during production.

With the Casmatic Zephyrus, Körber has introduced a revolutionary packaging concept responding to both the sustainability and e-commerce emerging market trends. With this new solution, boxes can be made out of 100% recycled cardboard, and once opened, the box can be closed again, keeping the product uncontaminated and easy to store.

The possibility to produce ‘’shipping ready’’ boxes allows customers to develop and increase their e-commerce business in a simple, fast, and personalised way.

This article was written for TWM by Nicolò Squarzoni, Product Manager at Körber Business Area Tissue.