Sections of most tissue and towel packaging systems in the industry can be supplied by four or five different manufacturers. Kyle Demerath, Director of Product Management, Packaging and Conveying Systems, PCMC, reports on the company’s coordinating vision after teaming up with STAX.

A converting line packaging loop is one of the most common systems found in converting. Without it functioning properly, production needs can be slowed, or worse yet, stopped. Despite that criticality, these systems have often been afterthoughts, incorporating pieced together independent modules without a coordinated vision of how they should function. The usual result is an expensive system running far below its potential, but this does not have to be the case.

Coupling the latest innovations in machinery with Conductor, a patent-pending approach to line integration, PCMC and STAX can provide a coordinated system vision and the right pack loop on any project. With the ability to verify the design through simulation before ever cutting steel, the result is a project executed with confidence, providing peace of mind and maximum productivity for the end customer.

A major factor in why most tissue and towel packaging systems in the industry lack vision is that the modules are supplied by a multitude of original equipment manufacturer (OEM) vendors. Wrappers may come from one vendor, while bundlers or case packers come from another.

Add in conveyor and palletising and the total number of vendors for a pack loop system that is meant to run as one interconnected network may be as many as four or five. Each OEM, specialising in a particular module, leaves the integration up to the end customer. Coordinating these distinct modules into a well-integrated system is no small task and the trend has been that converters have less and less capacity, desire, or knowledge to take this on. Too often, the outcome is a suboptimal system that is labour intensive and limits production.

This problem is certainly not new, and vendors have offered solutions to ease this pain by synchronising the various OEM modules. While this helps, a primary issue is that the integrator is often working without complete process knowledge of each unit. Without possessing this knowledge, the integrator is limited in their ability to interconnect the modules, and the solution is only a layer on top of independent modules. Too often this results in a system that is simply turned off because it resulted in lines that did not run smoothly, choked production, and resulted in more downtime and operator intervention.

There is a simpler way. By using a single source provider for the pack loop and allowing that OEM to craft a coordinated vision based on the needs of the project the system can be created from the ground up to work in harmony and optimise production.

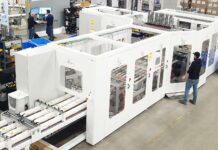

Packaging systems can vary considerably from project to project. However, a single-source OEM needs to have a wide-ranging product line to effectively address these wide-ranging needs. This is where the PCMC-STAX partnership applies. With the combination of flow and reciprocating technologies, conveyor solutions, case packing, bundling, and palletising solutions, PCMC-STAX offers an optimal solution for any project. Whether the vision of the line is high throughput “power SKUs” or a flexible, wide format system, PCMC-STAX has the equipment.

That said, having the right machines does not guarantee that a pack loop will perform at the highest possible level. It is necessary to be deliberate in all areas of the design to provide a pack loop that is both operator friendly, cost efficient, and reliable. To do this, PCMC-STAX use advanced simulation software to model the pack loop design prior to ever cutting steel.

This simulation work identifies potential bottlenecks such as short conveyors, devices too close together, and even poor sensor locations. Left unidentified, these issues can cause problem inducing speed fluctuations and extra machine stops, which ultimately result in lost production.

This advanced simulation capability can also be used to compare theoretical production numbers from layout changes, such as shorter or longer conveyors or different control methodologies. Ultimately, the simulations demonstrate that PCMC’s line integration method, Conductor, reduces rewinder stops and increases product out the door. Once these integrated and validated systems hit the converting floor, they are ready to run with PCMC’s line integration method, Conductor, taking centre stage. By modeling the pack loop system in real time as a digital twin, Conductor fluidly manages the backlog of each machine to an ideal amount, optimising runnability and reducing stops without the need for operator intervention, freeing them up for more critical tasks.

Overview screens and messages notify operators if there is a condition that requires attention somewhere in the pack loop. Finally, if the accumulator is filling up because the pack loop is limited in capacity, Conductor can slow the rewinder to minimise downtime and reduce the mean time to recovery. PCMC-STAX can take on the full responsibility of the pack loop as a single source provider, eliminating the need for converters to manage multiple OEMs. Converters simply provide the project requirements and allow the combination of industry experience, advanced simulation, line control innovation, and a clear singular vision will result in peace of mind that their truly integrated system will make the most of their converting line.

This article was written for TWM by Kyle Demerath, Director of Product Management, Packaging and Conveying Systems, PCMC.