By Pöyry Management Consulting’s Pirkko Petäjä and Jyrki Latvala

In an ever more challenging business environment, top experts suggest how the industry should manage a cost effective delivery chain in TWM’s Distribution Special Feature

An economic downturn and shifting global economy has created a business environment with higher demand and supply variability than before. As revenue bases have been changing, the need to improve competitiveness in terms of costs, quality, customer service level and price has become increasingly important.

- How to compensate the impact of the increasing sea freights (sulphur emission directive)?

- How could value be created for customers in the value chain (better steering by RFID)?

- How is the sales and supply chain performance rated compared to the main competitors?

- Lack of visibility to cost accumulation along the value chain typically causes sub optimisation and thereby limits the overall performance and cost competitiveness.

- Reporting structure and steering KPIs should contribute to the coordination and steering of the value chain as a whole.

‘The increase to costs in order to comply with the new sulphur content requirements is estimated at some +30% regardless of how the issue is solved.’

Tissue is bulky and expensive to transport

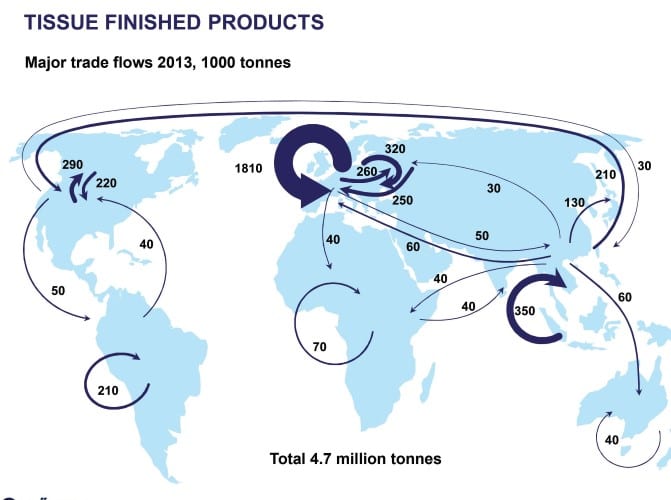

A normal 40 feet container can carry 25 tonnes of pulp, 12 tonnes of tissue jumbo reels, but depending on category only 6-8 tonnes of finished products. Therefore transporting tissue jumbo reels is about twice as expensive and transporting of finished products at least three times as expensive per tonne as transporting pulp. The high transportation costs are one important reason that has limited tissue trade flows over longer distances; due to the high transport costs tissue has mainly remained as a local or regional business.

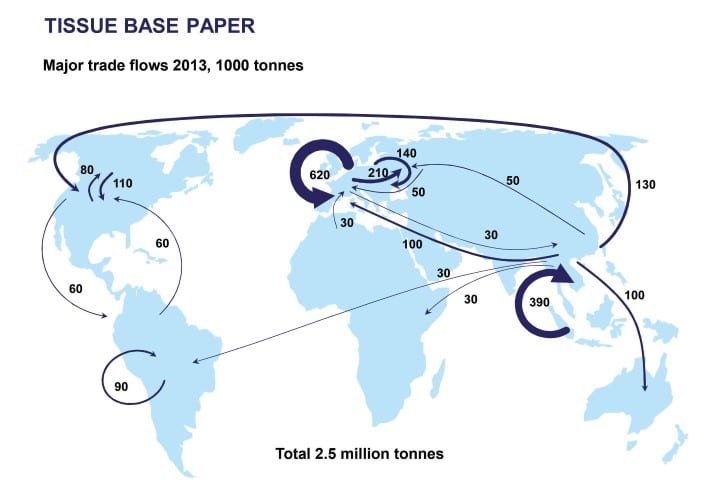

Main tissue trade flows

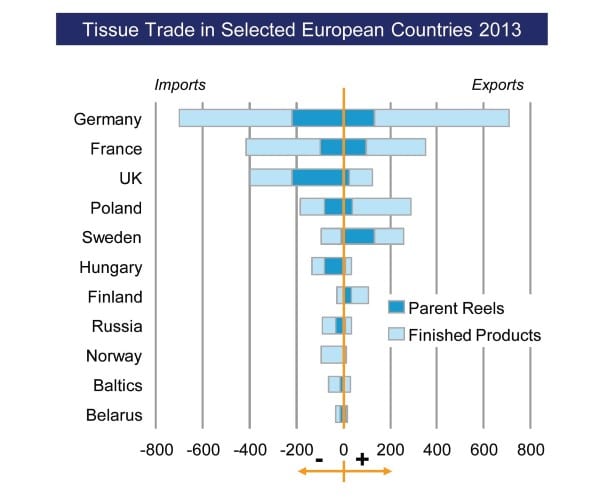

Though tissue does not travel well over very long distances, within Europe the trade over borders is quite significant, and managing the distribution costs is an essential part of a competitive tissue business. Over 30% of tissue market volumes is traded over borders within Europe; the largest markets in the middle. For instance Germany both imports and exports some 700,000tpy.

New challenges for Nordic sea transports include sulphur directive

Tissue producers are facing extra challenges for transports in the Baltic Sea and North Sea region when stricter provisions on sulphur emissions from shipping came into force at the beginning of 2015. At the start of the year the sulphur limit for marine fuels was cut to 0.1% in SOx (sulphur oxide) emission control areas in the Baltic Sea, the North Sea and North America’s sea areas.

This means reduction of the emissions to one tenth of the previous limit; from 1% to 0.1%. Baltic Sea, North Sea and the English Channel belong to a specific control zone regarding sulphuric emissions where this strict requirement was realised from the beginning of the year.

This new limit can be reached with basically two mechanisms; by changing to low sulphur content fuels or by investing in removing the sulphur from the emissions. Both ways have an impact on costs, the latter also through the impact of reduction of the cargo space.

The increase to costs in order to comply with the new sulphur content requirements is estimated at some +30% regardless of how the issue is solved.

The new directive puts different regions to unequal positions. In the Mediterranean the sulphur content of the marine fuel can be 3.5% until 2020. At that point also in all other southern European seas the sulphur limit must be 0.5%. Globally there is still an opportunity to postpone the schedule by five years.

Obviously this is a disadvantage for all businesses requiring transportation in the Baltic Sea, North Sea and the English Channel area, but especially it concerns tissue which is bulky and has higher transportation costs to start with.

‘There are ways to improve the delivery chain cost structure to compensate the impact of the increasing sea freights.’

Tissue trade in the Baltic and North Sea geographical regions is remarkably dependent on transportation by sea.

The cost structure of the delivery chain can be improved

There are ways to improve the delivery chain cost structure to compensate the impact of the increasing sea freights. Based on Pöyry’s experience, savings of between 5-15% can be realised throughout the delivery chain, which typically translates to 0.5-1.5% EBIT, depending on project scope.

Typical improvement areas include:

- Forecasting accuracy and information visibility throughout the value chain improving e.g. planning of the transports (routing and co-operation with different players in the delivery chain)

- Technical solutions in the vehicles to increase the load in a normal truck can be investigated (e.g. two layers of pallets in a truck)

- Delivery chain and logistics network optimisation (converting strategy and optimal location)

Improving delivery chain control may also help

Improving the delivery chain control might also be a way to make the chain more efficient and lower the costs. Radio Frequency Identification (RFID) technology is one way to improve the delivery chain control. It refers to small devices that consist of a small chip and an antenna; the chip is capable of carrying data.

The RFID device serves the same purpose as a bar code or a magnetic strip on the back of a credit card; it provides a unique identifier for that object. Just as a bar code or credit card magnetic strip must be scanned to get the information, the RFID device must be scanned to retrieve the identifying information.

A significant advantage of RFID devices over the bar codes is that the RFID device does not need to be positioned precisely relative to the scanner. We’re all familiar with the difficulty that store checkout clerks sometimes have in making sure that a barcode can be read.

In contrast, RFID devices will work within a distance of the scanner. For example, you could just put all of your groceries or purchases in a bag, and set the bag on the scanner. It would be able to query all of the RFID devices and total your purchase immediately. Obviously this has many applications in the distribution chain.

It is only recently that the ability to manufacture the RFID devices has reached the point where they can be used as a “throwaway” inventory or control device. When the device has reached a cost of less than Euro six cents it has become possible to take it into wider usage.

‘One reason that it has taken so long for RFID to come into common use is the lack of standards in the industry.’

One reason that it has taken so long for RFID to come into common use is the lack of standards in the industry. Most companies investing in RFID technology only use the tags to track items within their control; many of the benefits of RFID come when items are tracked from company to company or from country to country.

In addition to identification RFID devices can even measure some properties of the object they are attached to, for instance moisture content.

Obviously the device could improve the control of the tissue delivery chain and make the handling simpler. A compatible scanner could be located in a storage, in a terminal on board the vessel or when loading or unloading a vehicle. The information it carries can even create additional value to the product along the delivery chain. By efficiency improvements, reduction of losses, inventory turnover time improvements the better control can reduce costs. Especially in tissue where the shipments are typically much customised the benefits are obvious.

Summary

- Due to its bulky nature tissue is not transported very long distances. Tissue transport costs are typically two to three times higher than for instance the transport cost of pulp.

- Within Europe tissue trade over European borders is quite common and accounts for over 30% of the European market volume.

- In the Nordic area the sea transport is facing new challenges as from the beginning of the year a new sulphur directive entered in the force increasing the cost of sea freights by +30%.

- Better planning for delivery chain helps to compensate for the increasing costs; routing optimisation, co-operative means, larger shipments, larger vessels or trucks belong to the options that should be investigated.

- Better delivery chain control by using a RFID device may help to reduce costs and adds value to product later in the delivery chain.

- There are several ways of improving the cost effectiveness in the tissue delivery chain and sometimes an outside view might help. Pöyry’s logistic function has vast experience in various assignments targeting to designing a cost efficient delivery chain.

Pöyry Management Consulting is the leading advisor to players within the global paper, pulp, packaging and hygiene sectors.