The tissue industry, like all production systems, must find the answer to the planet’s plastic problem. Many companies are already advanced in research. Pirkko Petäjä, principal at ÅF Pöyry AB Management Consulting Division, examines the latest best-hope developments.

Plastic recycling and bio-based plastics

The world is crying out for a solution to the plastic problem, not only because of the huge amount of fossil-based oil that is needed for its production, but also because too often used plastics end up discarded in nature.

The annual plastics production is reaching some 400 million tonnes. When it comes to the tissue industry, plastic has been intrinsic to tissue product packaging, and plastic materials play a fundamental role in protecting, preserving, transporting and promoting the tissue products. For this reason the tissue industry and its interest groups, particularly clients, have been increasingly concerned about the global plastic waste problem.

While tissue production is developed towards more and more sustainable processes and raw materials, tissue is typically packed in virgin plastics PE/PP in its primary and secondary packaging and also the pallets are wrapped in plastics. This destroys the image of a sustainable product and increases for its part the accumulated world plastic waste problem that is already alarming.

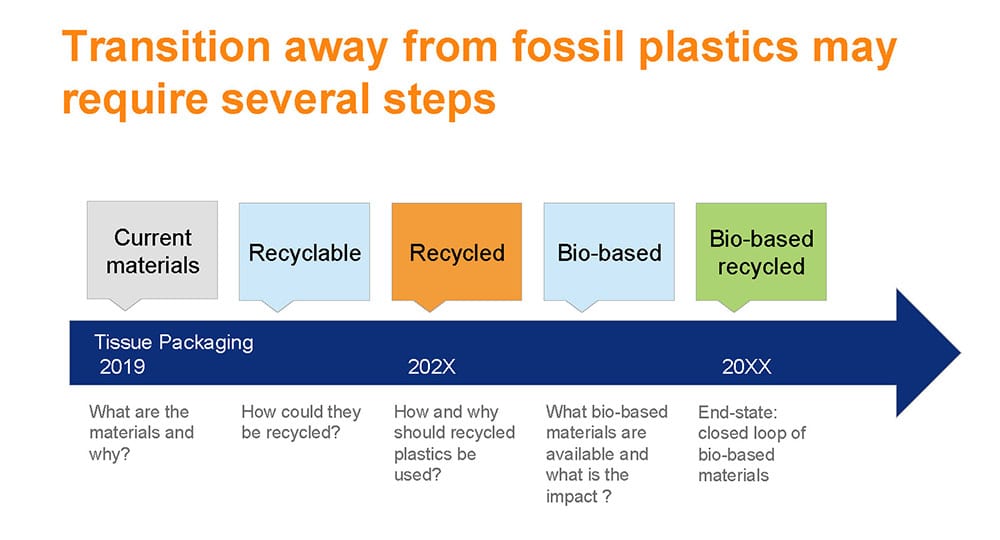

The transition away from fossil plastics may require several steps and phases. The requirements in the tissue packaging, quality and quantity, solutions available, achievable schedules, costs and future developments, etc, should be carefully studied and evaluated to find the right pathway.

What is required from the new solution? First of all it must perform in the package and do the job it is used for. It also needs to run increasingly automated, fast high-performance production lines. Whatever it is it must be available in large quantities and at reasonable prices.

Recycled plastic is a good starting point. The European Union has recently voted to ban single-use plastics by 2021; recycling would remove at least the single-use.

However, the package must be usable in economically sustainable recycling chains and compatible with existing recycling systems. It can take time to establish deposit schemes for tissue packaging but it can work as it works in many places for bottles and cans. However, recycled plastic is still plastic, of fossil origin, and can still end up in nature. It is also perceived by consumers as plastic, and not as particularly sustainable.

The second phase is to add bio-based content to the plastic feedstock. However, bioplastics, plant or animal-based, are still very expensive. In addition, they are not available in the quantities needed. A close loop of bio-based recycled plastics may be the desirable end-state but it is still really far away and the bioplastics alone are not a practical solution any time soon for the whole tissue industry’s needs.