Please visit www.sodra.com/en/Pulp/ for more information about Södra Värö tissue pulps.

It is no secret that the proportion of hardwood in tissue paper has risen. The less softwood pulp in the mix, however, the better that softwood needs to be. Södra Cell Värö’s process and the raw material it uses are both ideal to serve tissue makers. An extensive rebuild resulting in increased capacity and enhanced quality is also vital to support customer growth.

The tissue market will be vital to Värö’s future and this will be reflected in the pulp characteristics the mill delivers. The tensile from softwood fibre on which tissue makers rely cannot be achieved by “just any old softwood” when used in relatively small quantities, particularly if softness is also required, as of course it is with tissue. Södra has ensured that its Värö tissue pulps deliver just the fibre which tissue makers need.

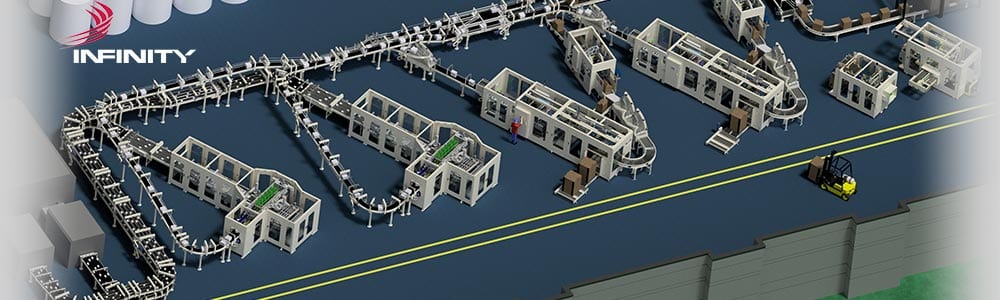

- In the upgraded woodyard the raw material which is best suited to tissue production is now selected more deliberately than ever before.

- Following debarking, the chipping process has been upgraded to provide a much more even chip size into the digester. If a pulp mill has to deal with a mixture of large and small chips, the degree of digestion is more random, a challenge which Värö has now tackled.

- The digestion process, through better chip-size management and other proprietary improvements, has been optimized over the past decade to capture the full potential of the raw material, in particular tensile.

- The fibre consistency which Värö has achieved allows tissue makers to make fewer adjustments to the process, such as the degree of refining, and this can improve runnability. It can also have a positive effect on final product characteristics – the less refining that is necessary to boost tensile, the less energy consumed and the softer the tissue which can be produced with the pulp.

- Värö can meet the certification requirements of tissue makers, be they PEFC, FSC or both. From early next year the mill will offer both ECF and TCF pulp,

Market expectations are constantly rising in terms of softness and tensile, and Värö is prepared for this. It is also now in a position to assure the fibre supply required to meet its customers’ growth needs. This project allows Södra to set the pace in tissue pulp for the foreseeable future.