Brazil’s Suzano has confirmed it will start up a Valmet-supplied complete tissue paper making line, tissue converting equipment and a biomass boiler at its Aracruz mill.

This is Valmet’s first combined order with tissue making and tissue converting lines following the acquisition of Körber’s Business Area Tissue in November 2023.

The investment is in response to an increase in demand by Brazilian consumers for high-quality tissue products, and start-up is scheduled for the first quarter of 2026.

The tissue making line and biomass boiler orders are included in Valmet’s orders received of the fourth quarter 2023 and the tissue converting equipment order of the first quarter 2024.

The value of the total order will not be disclosed but is expected to be around €100m.

Jean Moraes, Suzano’s Corporate Engineering Executive, said: “Valmet’s state-of-the-art solutions will allow us to expand our tissue products capacity by a new production line in Aracruz mill.

“This meets our needs in terms of business strategy, production capacity, cost efficiency, and sustainability.

“Valmet’s proven technology, combined with the ability to deliver a 100% integrated line from tissue machine to conversion, and consistent results in its solutions were important factors in the decision for these new investments.”

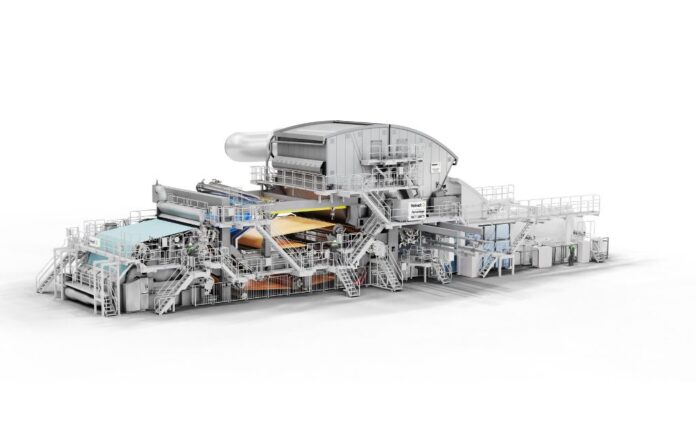

Valmet confirmed that the scope of supply includes a complete tissue production line including Advantage DCT 200 tissue machine with OptiFlo headbox and Yankee cylinder with an annual production capacity of 60,000 tons, and that the tissue making line and converting lines are optimised to save energy.

It will also be featured with the Advantage tissue technology including ViscoNip press, ReDry, AirCap hood with Air system, WetDust systems and a SoftReel reel.

A biomass boiler that uses bubbling fluidised bed (BFB) technology will also be delivered, increasing the mill’s energy efficiency.

The new Valmet bubbling fluidised bed (BFB) boiler is scheduled to start operating in the last quarter of 2025 and will use biomass to produce steam, which is used in the cellulose process and in the generation of electrical energy.