Russia’s Arkhbum Tissue Group has invested in a Valmet-supplied Advantage DCT 200 HS tissue line for start-up at the company’s mill in Vorsino, Kaluga.

Start-up of TM2 is planned for the first quarter of 2023 and the machine will have a width of 5.6m, a design speed of 2,000m/min, and produce 70,000tpy of high-quality napkin, toilet, and towel grades.

It will use virgin fibre from the owner’s own pulp mill.

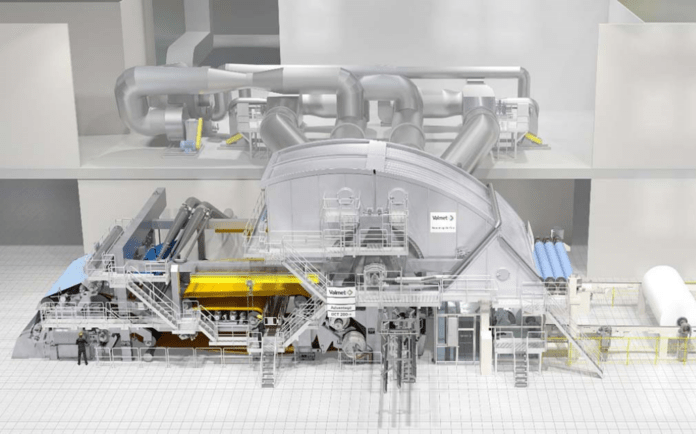

Valmet’s scope of supply includes a complete tissue production line including stock preparation systems, a Valmet Advantage DCT 200 HS tissue machine equipped with OptiFlo TIS II headbox, the Advantage ViscoNip press combined with Advantage ReDry and a Steel Yankee dryer.

It also features an AirCap Heli hood, WetDust dust system and a SoftReel, and complete clothing packages with Valmet Forming Fabric GMs, Valmet Press Felts STMs and Valmet Black Belt R ViscoNip belts. T

Arkhbum Tissue Group aims to reach a total capacity of 210,000tpy of high-quality tissue and towel products made from its own pulp.

The value of the order will not be disclosed, although a project of this size and scope is usually valued at around €20-40m.

Arkhbum Tissue Group provides its own brand Soffione products to consumers in Russia, CIS countries and Europe.