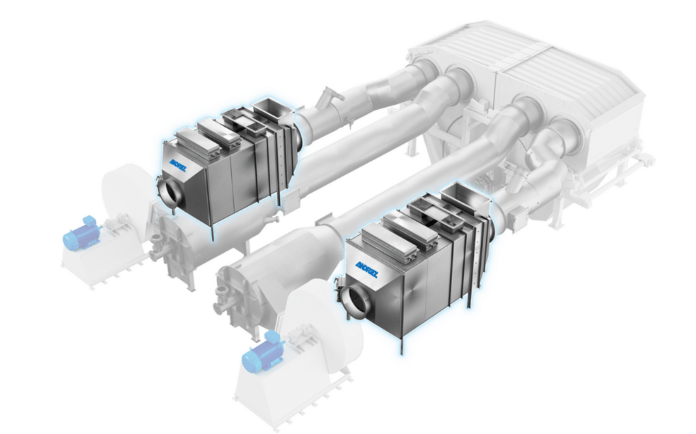

Andritz has targeted the reduction of carbon emissions and increased tissue production with its latest innovation, the PrimeDry Hood E.

The drying hood has an electric heating system that the supplier said helps tissue machine operators replace fossil fuel, thus avoiding carbon emissions.

Additionally, Andritz said the system offers increases in energy efficiency and production rates compared to conventional fossil-fuelled systems.

An order has already been placed with start-up planned for the end of this year.

George Nowakowski, Vice President Tissue Drying, Andritz Canada, said: “We developed the new hood in close cooperation with customers.

“It perfectly matches today’s need for sustainable and especially CO2 reduced high-quality tissue production.

“Having received the first order right after the market launch is the best proof that we are meeting our customers’ needs.”

The PrimeDry Hood E uses electric heating elements to heat the air flows in the hood.

As a result, the company said that carbon emissions from tissue machines can be reduced by about 70% from conventional gas-heated systems.

It said: “As the new hood does not require any combustion air, energy efficiency for the drying system increases by up to 4% compared to gas-heated systems.

“With its ability to achieve air temperatures of up to 450°C, it can contribute to higher production compared to steam-heated systems.”

The PrimeDry Hood E is also available as a hybrid model, with an air system that combines electric air heating elements with natural gas burners working in tandem arrangements.