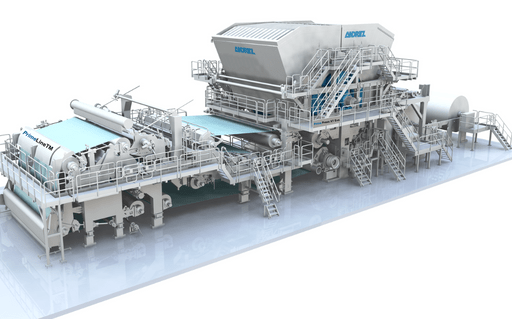

Brazil’s Bracell SP Celulose has boosted its high-quality tissue production capacity after investing in four Andritz-supplied PrimeLineTM W 2000 tissue machines to be installed at its mill in Lençóis Paulista, São Paulo.

Start-up is scheduled for 2024 and the lines will produce household paper such as toilet paper, napkins, handkerchiefs, towels and facial tissue.

The machines have a design speed of 2,100m/min and a working width of 5.68m.

Andritz’s scope of supply includes the stock preparation systems that will process slush pulp from Bracell’s own pulp mill, rewinders and roll handling, roll covers, machine clothing, shoe press belts, and additionally more than 100 units of high-efficiency process pumps.

All four plants will be equipped with the Metris X integrated distributed control system (DCS), which the supplier said “ensures optimal plant operation”.

Andritz added that the machines are equipped with fully cantilevered shoe presses for “easy dewatering and easy maintenance”, and 18 ft. Steel Yankees with steam-heated hoods for energy-efficient drying.

“The new tissue mill will be self-sufficient in steam and electricity consumption for the drying process, making it one of the tissue mills with the smallest CO2 footprint in the world,” Andritz said.

Bracell SP Celulose is part of the Royal Golden Eagle (RGE) group, which manages companies in the resource-based manufacturing industry. Among them is Chinese tissue producer Asia Symbol, which will start up three Andritz-supplied tissue production lines in the next few months.