By Solenis’ Todd Sarraf and Ronald Staib

In every region of the world, the tissue market is experiencing exciting expansion. Consequently, although the specific challenges and opportunities vary depending on the region, many shared challenges exist, including the consumer demand for improved quality at a reasonable price, the need to control manufacturing costs and asset efficiency and the desire to protect the environment by operating in a sustainable manner. Solenis, formerly known as Ashland Water Technologies, was formed through various mergers of several organisations including Hercules, Houghton, Dearborn, Quaker and Betz PaperChem. Over the past 10 years, Solenis has worked to develop a strong R&D process focused on innovation. This has resulted in the development of several unique capabilities, including process simulation, predictive tools and models. Recently, Solenis introduced several innovations that were developed specifically to address these shared challenges in the tissue and towel market.

Enzymatic Dry Strength

Dry strength is a critical functional quality parameter of tissue products. Previously, the use of a product to enhance strength has often resulted in a negative effect on softness or even increased costs. More recently, enzyme-based products were introduced and have shown some promise as well as some limitations, including product stability, cost-in-use and control of reaction. Solenis has worked to address the shortcomings that existed in the market, resulting in the development of several new HercobondTM enzyme-based products.

Cellulase activity and storage stability

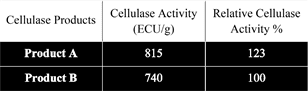

Not all cellulase enzymes are created equal. Tests have been conducted to identify the best cellulase available to maximise performance and to develop new enzyme preparations that demonstrate product stability and synergistic effects on tissue dry strength properties. Table 1 represents the relative enzyme activity levels of the Hercobond product A versus the base enzyme, Product B. Once improved efficiency and stability were achieved by adjusting the product formulation and differentiating performance was demonstrated, the technology was validated in several different operations.

Mill trial – improved performance over base enzyme

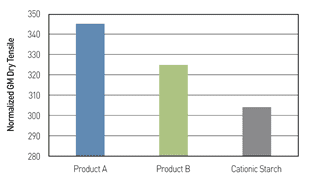

A tissue machine used a liquid cationic starch on a Crescent former to produce bath tissue using 100% deinked pulp (DIP). The aim was to determine if Hercobond Product A was superior to base enzyme Product B in a commercial trial. A two-day evaluation was conducted to compare the two cellulase products. The cellulase product dosages were 1.75 pounds per tonne dry recycled DIP based on the same cellulase active. The bath tissue product had a basis weight of 9.1 pounds per 3,000 square feet. As shown in Figure 1, both Product B and Product A demonstrated better dry tensile strength performance than the liquid cationic starch. However, Hercobond Product A yielded a 14% improvement in dry tensile strength compared to the starchand Product B achieved only a 7% improvement over the starch. The new Hercobond products were proven to be extremely effective in developing strength while minimising the negative effect on quality and cost-in-use.

Fines management

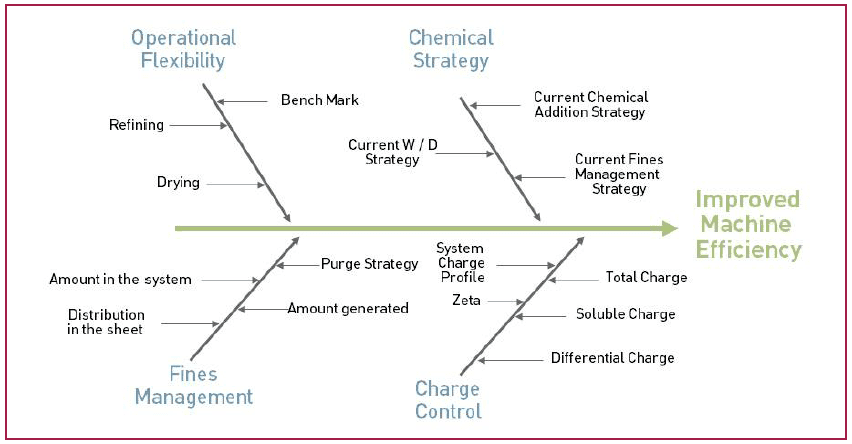

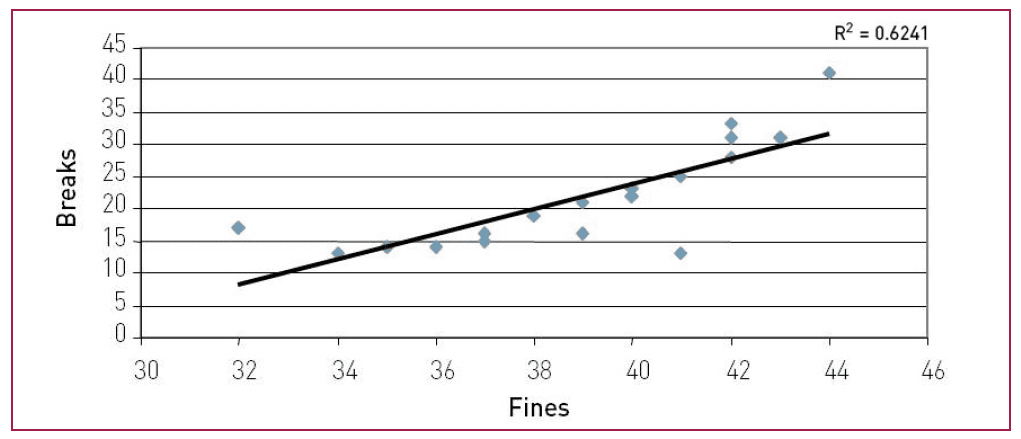

Premium tissue and towel producers constantly strive to optimise their operations to produce strong, soft, absorbent products that exhibit minimal quality variations. To minimise finished product variations and to maximise productivity, tissue producers often centerline critical operating parameters, such as Yankee pressure, refining energy, sheet moisture at transfer points, etc. Fines are typically an overlooked variable in these systems that can dramatically effect finished product quality as well as machine efficiency. Recently, due to environmental pressures and waste costs, producers have been forced to limit sewer losses. As a result, fines management has become a more critical to improve sustainability efforts. Several different strategies are currently used to manage fines. The most effective results are achieved by operational procedures and chemical approaches. See figure 2

PerForm™ SP advanced retention and drainage aids – “an enabling” technology for the T&T market

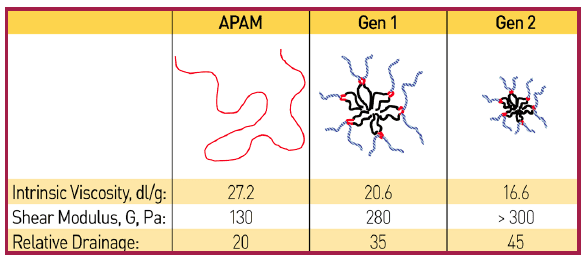

Perform SP technology has been used effectively to manage fines and to improve chemical efficiency in systems using wet strength or another cationic co-factor to improve fines retention, wet strength and operational efficiency. The second-generation PerForm SP technology delivers a unique, structured, micro particulate that is effective in improving retention while having minimal to no impact on formation that a standard APAM has exhibited in the past. Figure 3 illustrates the sequential process modifications used to produce Generation 1 (G1) and Generation 2 (G2) products compared to a conventional, unstructured anionic polyacrylamide (APAM) retention aid, thereby highlighting the change in polymer structure and performance. The G2 product is a smaller, more congested particle as illustrated by the reduced intrinsic viscosity and increased shear modulus. These structural changes in the molecule correlated to improvements in on-machine performance.

Case history

A towel Crescent former running at speeds in excess of 6,000fpm and producing 250 tonnes per day running virgin fibre was looking for improvements in fines management to improve machine cleanliness, to reduce blade changes and to improve wet strength efficiency. Results included:

- Reduction in dry strength chemistry by 75%

- Reduction in clarifier polymer use

- Reduction of five pounds/tonne of wet strength (while increasing wet over dry)

- Ability to increase machine speed

- Reduction on blade changes

Wet strength

Polyaminopolyamide-epichlorohydrin (PAE) resins were developed more than 50 years ago and have become the predominant chemistry used in the paper industry to manufacture wet-strengthened paper. Over the last two decades, PAE producers focused product improvement and development efforts on two main initiatives: improving PAE resin efficiency and achieving paper manufacturers’ improved health and sustainability objectives. The latter has been driven primarily by regulatory initiatives focused on “cleaner” products with much lower levels of epichlorohydrin (epi) by-products and much lower levels of adsorbable organic halides (AOX).

Development of high efficiency PAE products

The reactivity in PAE resins arises from quaternary ammonium functionality (azetidinium) that provides “permanent” cationicity to the polymer, which enhances retention of the active polymer on pulp fibres. Additionally, the azetidinium functionality reacts with carboxyls on pulp fibres (co-crosslinking) and self-crosslinks (homo-crosslinking) to provide a wet strong structure. Highly efficient resins typically maximise the azetidinium (AZE) level and the molecular weight (MW) of the resin while maintaining gelation stability. Recent research efforts by Solenis have led to a breakthrough in resin design such that a family of resins with 12.5-30% solids can be manufactured without compromising performance or gelation stability and is now available. These new, high efficiency, high solids PAE resins also have a relatively low level of 1,3-dichloropropanol (DCP) and 3-monochloropropanediol (MCPD) and therefore have a good environmental profile.

Regulatory, health and sustainability improvements

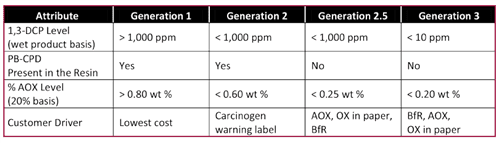

In PAE wet-strength resins, two types of organic chlorine species exist: (1) free epichlorohydrin by-products, 1,3-dichloropropan-2-ol (1,3-DCP), 3-monochloropropandiol (3-MCPD), and unreacted epichlorohydrin (typically at very low levels, thus will not be considered further); and (2) polymer bound organic chlorine (PBOX) species. PBOX include: (a) aminochlorohydrin (ACH), the principle species formed from the initial reaction between epichlorohydrin and the amine groups of the poly (adipic acid-co-diethylenetriamine) prepolymer; and (b) polymer bound CPD (PB-CPD), the species formed from the reaction between epichlorohydrin and the acid end groups of the prepolymer. As PAE resins evolved, the product definitions of AOX measurement and epi by-products have become inconsistent across product “generations”. Table 2 summarises the recommended definition for each product generation (G1, G2, G2.5 and G3).

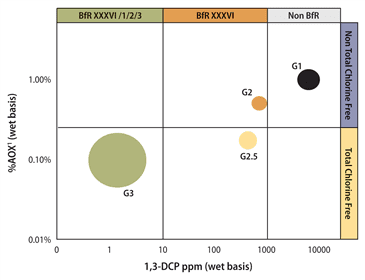

Solenis was the first manufacturer of PAE resins to address customers’ concerns about free epichlorohydrin by-products (1,3-DCP and 3-MCPD). These substances are considered to be carcinogenic. For products that contain more than 1000 ppm of 1,3-DCP (G 1 wet strength resins), the Safety Data Sheet usually contains a note identifying the presence of 1,3-DCP and explaining that it has been shown to cause cancer in laboratory animals and that it is listed as a possible human carcinogen by the International Agency for Research on Cancer. Customers concerned with worker safety should consider selecting G2 PAE resins. In Europe, 1,3-DCP is considered to be a Substance of Very High Concern under REACH. Consequently, no wet strength resins that contain more than 1,000ppm of 1,3-DCP are manufactured or imported into the European Union. The free epichlorohydrin by-products (1,3-DCP and 3-MCPD) are volatile organic compounds (VOC) and are potential contributors to mill VOC emissions. The total amount present in the PAE resin has to be considered by mills and customers that have limitations on VOC levels in their local operating environment.

Another factor of regulatory concern is adsorbable organically-bound halogens (AOX) in the tissue product and in mill effluent. Allowable AOX levels are set by governmental regulations and non-governmental guidelines. Free epichlorohydrin by-products can be contributors to AOX. Even when using G2 PAE resins (with < 1000 ppm of 1,3-DCP on a wet product basis) AOX limits can be exceeded because polymer-bound species, ACH and PB-CPD, are by far the main contributors to AOX.

Solenis developed a patented process to manufacture PAE resins that do not contribute to AOX in the paper or in mill effluent. The manufacturing processes for these wet strength resins, developed to eliminate PB-CPD species from the final product also reduce the level of ACH, thereby reducing the total AOX and PBOX content of the resin. These resins are suitable for manufacturers wishing to meet AOX effluent requirements and to produce BfR-compliant and Total Chlorine Free (TCF) grades of paper.

Case history: generation 2.5 PAE resin contributes lower OX in high wet strength towels for mills using TCF furnish

A European tissue mill making high wet strength towel (twin wire former, 22,500tpa, 1,650m/min) used a G2 PAE resin for most applications and was meeting BfR XXXVI requirements for kitchen towels satisfactorily. However, on certain grades, where a key parameter was to have low OX in the finished paper for specific supermarket customers, the mill was unable to achieve the necessary specification. Customer trials were run using Solenis’ G2.5 resin. Efficiency was improved compared to the incumbent G2 resin. Results from independent laboratory (ISEGA) testing showed the OX levels in the kitchen towel made with the G2.5 resin were much lower than those obtained with the previous program and comfortably below the limits set by the BfR.

New creping adhesive development

Maintaining sheet control on the Yankee dryer is critical to producing high quality tissue. As Yankee dryer temperatures increase and sheet moisture decreases, sheet control becomes more difficult to maintain. By investigating the relationship between adhesive structure and film properties, Solenis has developed a new creping adhesive, marketed as Crepetrol™ 9200, that provides superior sheet control under these harsh conditions.

Using an experimental design to assess structure-activity relationships was critical to this research. A design platform consisting of two polymers (a polyaminoamide and a proprietary copolymer) covalently cross-linked with epichlorohydrin was selected for the new adhesive. The polyaminoamide was expected to provide adhesion between the Yankee surface and the sheet. The second polymer was expected to provide both good film-forming characteristics and moisture handling capabilities. The crosslinker (epichlorohydrin) imparts thermosetting character to the final product and builds molecular weight.

Experimental Design

The experimental design elements included:

- Ratio of polyamide to copolymer

- Dosage level of epichlorohydrin

- Amine content of the polyamide

- Type of diacid monomer in polyamide

- Type of diamine monomer in polyamide

- Molecular weight of polymer polyamide

- Amine level in copolymer

- Molecular weight of copolymer

Computer modelling of the entire matrix prior to synthesis suggested some products would not be water-soluble, therefore, they were not synthesised. The half-factorial design led to production of roughly 120 different samples for study. Testing methodology to assess creping adhesive performance included using a proprietary Adhesion/Release Test (ART) developed by Solenis, as well as film persistence and film rewettability tests. The ART was used to test the ability of the experimental materials to function as creping adhesives. Dry ART testing mimics the adhesive’s performance at the creping blade. The sheets to be tested were prepared on Solenis’ pilot paper machine so that furnish and wet-end chemistry could be controlled.

All samples were compared to a control that was a standard thermosetting PAE (PolyaminoAmide-Epichlorohydrin) creping adhesive. Based on ART measuring 5-second cure time dry adhesion, initial structure-activity-relationship conclusions were drawn. Factors that effected the design included diacid chain length, epichlorohydrin loading, amine loading in the copolymer, and amine type in the polyamide.

A second series of performance tests used a wet ART test. Compared to dry ART testing, wet ART testing introduces two new parameters, the initial sheet moisture and the amount of time that the dried adhesive film is allowed to stand in contact with the wet sheet. The three-dimensional structure provided by the covalent crosslinking of the two polymers provided improved adhesion relative to standard commercial PAE adhesives in some of the experimental samples evaluated in both the ART and wet ART tests, but further performance assessments were needed to select a final candidate and to understand the structure-function relationships and improved adhesion.

If too much of the adhesive is removed with the sheet by the creping blade, the adhesive will not provide good sheet control or effective Yankee surface protection. One way to test the ability of the adhesive to stay on the Yankee is to test the solubility/strippability of a dried film of the polymer by applying 60 °C swirling water for 60 seconds. Unfortunately, in terms of persistence, little differentiation appeared between the selected experimental samples. A final performance test assessed the ability of the film to absorb water. The ability of a cured adhesive on the Yankee surface to sufficiently re-wet when contacting the incoming wet web is important for adhesion and sheet control. Films of the adhesive or mixtures of adhesive and PVOH were cast and dried, and the amount of weight gain when the films were exposed to a fixed amount of water was assessed. This test revealed that one sample was significantly different from the others and demonstrated the most consistent level of water uptake across all the levels of PVOH in the system. This new creping adhesive has been marketed by Solenis as Crepetrol™ 9200.

Case histories

Two case studies verify the effectiveness of the Crepetrol™ 9200 adhesive. In the first case study, an older, fairly slow tissue machine running 100% recycled furnish was switched from a standard thermosetting PAE adhesive to the new product with all other parameters remaining constant. After the switch was made, the sheet was visibly tighter coming off the Yankee and the customer was able to remove six pounds per tonne of wet end debonder while maintaining the same level of softness (handfeel panel testing). The crepe structure of the sheet was visibly better to the naked eye. In the second case study, a machine producing facial tissue from 100% virgin NBHK ran nine creping adhesives head-to-head to determine which adhesive allowed them to produce the softest sheet with all other parameters being held constant. According to the panel testing conducted after the trial, Crepetrol 9200 produced the best handfeel score.

Todd Sarraf is global marketing director, tissue and towel, Solenis and Ronald Staib is technical director, global technology, Solenis.

[box type=”info”] REFERENCES

(1) Pascal Rivard, Qu-ming Gu “Novel Enzymatic approach new possibility for recycled Tissue and Towel Manufac2turers”

(2) John Hochu, John Harrington “Second Generation Advanced Retention and Drainage Technology Continues to Improve Operational Efficiencies and Reduce Operating Costs”

(3) Mark T. Crisp and Richard J. Riehle “Polyaminopolyamide-epichlorohydrin (PAE) Wet Strength Resins for Improved Health and Sustainability”

(4) Joseph Mahoney “High Performance Creping Adhesive” [/box]