Technical Theme: key technical developments from across the packaging machinery industry. A TWM report. By Massimo Franzaroli, president of Pulsar Engineering

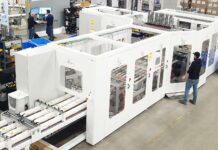

Pulsar Engineering has broadened its range of Quatis machines with the launch of the Quatis Bags machine. The range and latest addition aims to increase quality control of tissue products, both wrapped and un-wrapped.

This latest development enriches the range of inspection machines designed by Pulsar Engineering, which includes Quatis Rolls that check the suitability of un-wrapped products (that are positioned next to the log saw) and Quatis Packs (that check wrapped products).

This innovative technology relies on a powerful vision systems and complex algorithms for image analysis that allow the inspection of each product according to present parameters and single user requirements.

By controlling each product, the machine provides elaborate analysis of the frequency and causes of noncompliances, giving the opportunity of adequately improving the settings of the machines upstream, thus increasing the line efficiency and the overall production capacity.

Every Quatis machine is designed as a stand-alone unit, allowing operators to install it within new or existing converting lines.

Quatis machines do not only simple inspect and analyse each product conveyed, but also provide a platform for the elaboration of all data stored, the generation of periodic reports and the

function of filtering and discharging non-compliant products.

The control of 100% of products on the converting line assures the lack of non-compliant products within.

For example, a production batch shipped to a large-scale retailer, and enables operators to monitor the nature and the entity of each non-conformity in order to match it with the operational data of the line.

Quatis Bags check a wide number of non-conformities, such as non-compliant back cross and side sealing, non-compliant print centering, incorrect roll orientation or missing roll, non-compliant logos or images and the presence of the handle.

The non-compliances of every inspected product are identified according to present recipes.

Since the amount of possible noncompliances is unlimited, Pulsar Engineering provides the possibility to define the non-compliances that best fit the products examined, creating real “tailor made” options.

This article was written for TWM by Massimo Franzaroli, president of Pulsar Engineering