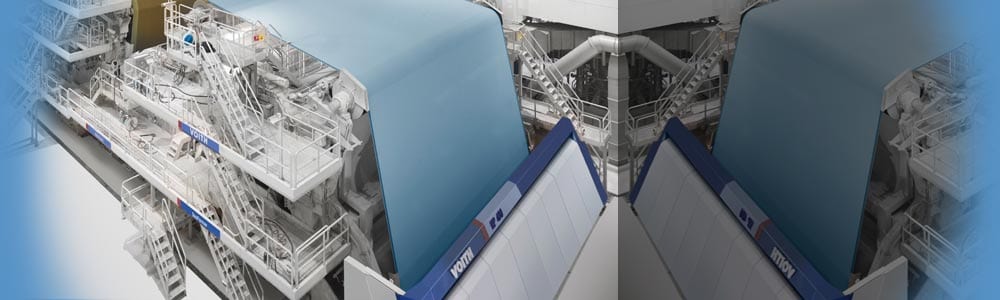

Voith has launched NipVision, a real time system that makes nip measurements possible while the paper machine is running.

The online and real-time measurement tool uses the latest roll cover technology, where a glass fibre is embedded in the roll cover that constantly transmits information from the nip.

The company said it is the first system to measure nip pressure, profile and the cover temperature while the paper machine is running.

The NipVision glass fibre sensors are very small, non-aging, flexible and chemically resistant.

They lie inside the cover, so that the roll application and dimensions remain unchanged.

In a statement, Voith said: “It is the only system which can measure temperature within the cover while the paper machine is running.

“This is a real benefit to the customer, given that a large number of damages result from temperature-related issues.

“Until now the source of poor profiles and sheet quality, increased sheet breaks and sudden roll cover damages have often been linked to a given press nip but, without any proof.

“With the help of NipVision such problems can be detected and hence prevented.”