By Pirkko Petäjä

In the German markets catering for certain environmental attributes is a ticket to play, while in many emerging markets their importance is still low.

Environmental issues continue to gain importance all over the world, but there are still differences with the level of interest in the various marketplaces. In Europe, especially in Germany, these issues are most forthcoming, while in emerging markets cost and profitability issues come before any sustainability or environmental concerns. When the market is mature, there is also a stronger need for differentiation based on environmental attributes compared to strongly growing markets where the demand is based on filling a basic need and penetration of usage.

The Middle East and North Africa, in relative terms, are the fastest growing tissue markets globally. In these markets, environmental and sustainability issues are today still far behind when you compare them with areas such as Europe. These issues are rising, but the markets there are not yet affected by these concerns. Energy in most countries is extremely cheap. Nobody thinks of replacing fossil fuels and only fresh water as a scarce resource has been addressed, mainly as a result of the economic impact and availability rather than as an environmental concern.

In Asia the focus is also sharpening, but topics are again different and the awareness is also clearly on a lower level.

Responsible and leading tissue companies have established high environmental standards in Europe

The leading tissue companies have sustainability issues high on their agendas. As with businesses such as SCA and Sofidel, many companies have established company-wide programmes and are very advanced in their environmental policies. These companies are also well respected and trusted by their clients and other stakeholders in this concern.

“In tissue, the technology to drive energy efficiencies means a reduction of heat demand in production.”

Environmental stakeholders include tissue companies, environmentalists/non-governmental organisations (NGOs), retailer chains, governments, institutions and other public buyers as well as final consumers that can be corporates or individual buyers. Environmental requests are much more driven by retailers, NGO’s and institutional buyers than by the final consumers.

Third party environmental certifications and labels address often multiple environmental attributes

Third party environmental certifications and labels are various and commonly used as marketing tools and aids for the suppliers to make the environmental performance claims credible. They are also often standard requirements set by the buyers.

Existing respected environmental certificates in tissue often address multiple environmental attributes. Eco-labels

are often national or sub-regional such as Green Seal and EgoLogo in North America, Blue Angle in Germany, Nordic Swan in Scandinavia, EU Flower in Italy, France, Portugal and Belgium, and also the WWF label can be used in developed markets making credible claims on sustainability requires looking beyond only one issue, for instance the forest certification issue. The main issues emphasised in developed markets include:

- Impacts on climate change; the role of greenhouse gas emissions from operations

- Safeguarding forest resources, origin of fibre, forest certification

- The use of fresh water resources

- Effluent quality and treatment

- Chemical usage and toxicity

- Recycling

- Sludge disposal and landfilling

In order to fight the climate change, CEPI 2050 Forest Fibre Industry (FFI) has published a Roadmap to a low-carbon bio-economy. The tissue industry is also part of the FFI and the 2050 Roadmap concerns tissue as well as other paper producers. In tissue, the technology to drive energy efficiencies means a reduction of heat demand in production i.e. a focus on drying and reduction of paper/package weights and packaging materials. In recovered fibre it means better sorting of materials, reduction of co-mingled collection where possible and also keeping the recovered fibre in Europe. On the energy side it means focus on CHP boilers using biomass. Many tissue producers increase the use of renewable energy sources, focus on improving energy efficiencies and invest in co-generation systems.

Regarding origin of fibre; preferably FSC certification, and if not labeled, at least using ‘fibre from controlled sources’ is a must in certain regions. Nothing extra is paid for this, but for private label it is a necessity in order to sell to certain retailers that are for their part pressed by the NGOs.

Low effluent levels and less fresh water usage have not only an environmental but also an economic impact.

Chemical toxicity, requirement of TCF bleaching for pulp has been a rising issue lately. It is a requirement primarily in Germany and tissue producers often combine the TCF and FSC certification requirements; the availability of such pulp can be limited.

‘The leading tissue companies have sustainability issues high on their agendas.’

Recovered fibre is not often used, but can be a requirement of certain clients. Deinking sludge disposal has lately been an increasing environmental concern. In many places landfilling sites are not available and the utilisation of the sludge in different ways is requested. Usage as an energy source is the most common, leading to investments in incineration facilities. The flue gas scrubbing has been much discussed. As the energy consumption for tissue mills (as half is gas) is rather small, and the amount of rejects from deinking rather high and difficult to burn, these facilities are often outsourced.

Unbleached non-wood is rising in China

At CIDPEX 2014, the tissue paper conference only had one presentation referred directly to energy savings – no other topic referred to anything ‘environmental’. However, the globally-based responsible tissue machine manufacturers’ presentations included a high environmental awareness and standards evolved to their machine designs based on requirements elsewhere.

In the Disposable Hygiene Products conference, environment was not focused either. Wet wipes are rising and have a more central role in Asia than for instance in Europe. A couple of the presentations referred to flushability of wet wipes which is more a problem of plugging the sewer networks than an issue of impacting the environment.

Natural fibres, which flushable products usually contain, are a more sustainable raw material than the synthetic fibres.

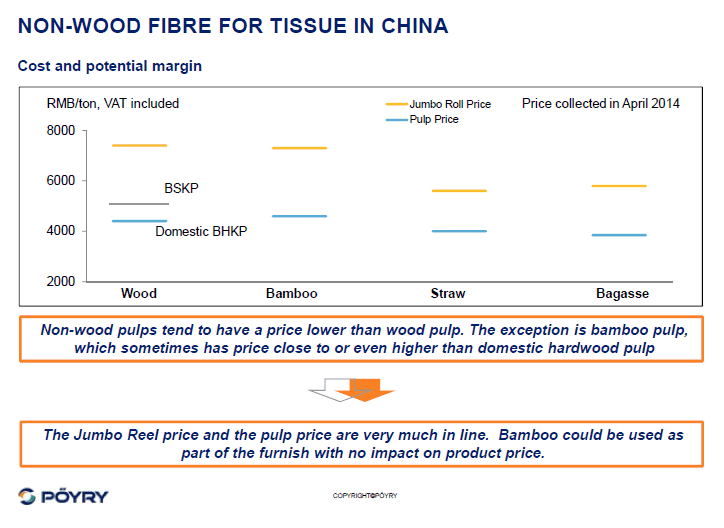

The most forthcoming environmental issue seemed to be the origin of fibre. In China, a ‘natural’ choice is used to promote non-wood products instead of the local wood.

Products manufactured especially from 100% wheat straw and 100% bamboo were promoted quite strongly. The emphasis is that non-wood pulp is not bleached to appear more ‘natural’, and it also reduces the environmental impact in the production.

‘The existing respected environmental certificates in tissue often address multiple environmental attributes.’

Bamboo in particular is a relatively high quality fibre with good absorbency properties and strength due to the rather long fibres. Kimberly-Clark, which is striving to develop globally the use of bamboo, has made efforts to develop bamboo plantations near the use and it is also addressing the challenges of processing.

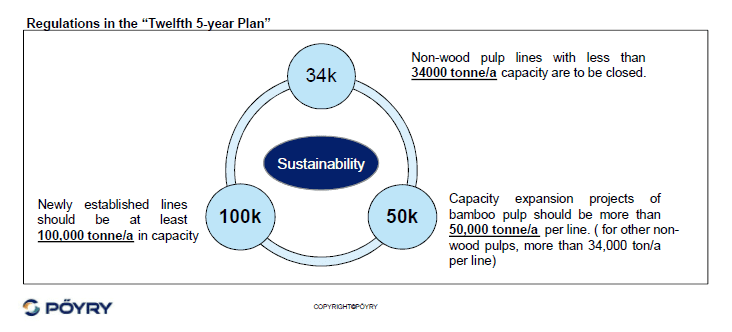

The environmental issue – especially with the Chinese non-wood pulps – is that the mills are too small to make chemical recovery systems financially feasible. In addition, the technical challenges with Silica, especially with high contents of it in rice straw, make recovery difficult or impossible. With many of the smallest mills, sustainability or environmental friendliness are the last words to connect with production. However, with the increasing size of mills and increasing fulfillment of environmental requirements, processing is becoming more and more environmental.

Stopping the bleaching contributes very much to the effluent quality – if recovery of cooking liquids and water treatment is taken care of, the unbleached non-wood products are truly ‘green’ and environmental.

The Chinese have aspirations to export these products out of China due to the increasing local overcapacity.

Summary

Environmental issues are becoming increasingly important for tissue businesses globally. In certain markets, for instance Germany, compliance with environmental regulations and a spotless ‘green’ reputation are tickets to play while in the emerging markets the significance of these issues is still considerably less.

Local issues are often the most interesting; in the Middle East, the use of relatively cheap energy is less interesting than the use of the scarce fresh water resources.

‘The Chinese have aspirations to export these products out of China due to the increasing local overcapacity.’

Third party environmental certifications and labels are commonly used as marketing tools and aids for the suppliers to make the environmental performance claims credible. In some regions these are often standard requirements set by the buyers.

The existing respected environmental certificates in tissue often address multiple environmental attributes.

Important environmental issues in developed markets include; climate change and GHGs, forest certification, use of fresh water resources, effluent quality, chemical usage and toxicity, sludge disposal and landfilling.

In China, environmental awareness is still in an emerging phase. Most visible seems to be the marketing of local unbleached non-wood products.

By improving the technology and reaching economically viable size of the plants, the unbleached bamboo and wheat straw products produced in mills with sufficient chemical recovery can be called truly ‘natural’ and sustainable.