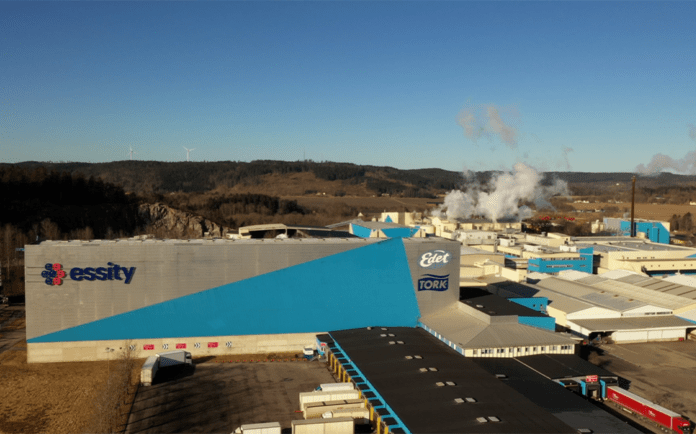

Essity has started testing of its first CO2 emission-free, large-scale tissue production at its Lilla Edet plant in Sweden.

By completely replacing natural gas with biogas, Essity said the plant will reduce its fossil CO2 emissions to zero during normal operations.

Successful shorter tests took place during the beginning of 2021 and the Lilla Edet facility will now conduct a longer test run replacing natural gas with biogas as energy to produce the Tork brand as well as consumer tissue products such as Lotus.

Both natural gas and biogas contain methane; Essity said that as Biogas is renewably produced through digestion of biological waste, it does not then give rise to fossil CO2 emissions.

The first deliveries of biogas reached the production facility on 22 March.

Donato Giorgio, President Global Manufacturing at Essity, said: “The ambition for our production facility in Lilla Edet, Sweden, to be the world’s first tissue mill with emission-free production.

“Supported by several successful shorter tests, we will now run the mill emission free for a longer period.

“We can then take the knowledge gained and explore using it in our other production facilities.”

By 2030, Essity aims to reduce its greenhouse gas emissions by 25% for its energy and electricity use, within the company and for purchased electricity, compared with the base year 2016.

Up until 2020, emissions have been reduced by 11% compared with the base year.