Marco Cirigliano, sales and application engineer, outlines why FIS Impianti’s new generation wrap is critical to preserve paper quality, hygiene, and avoid contamination.

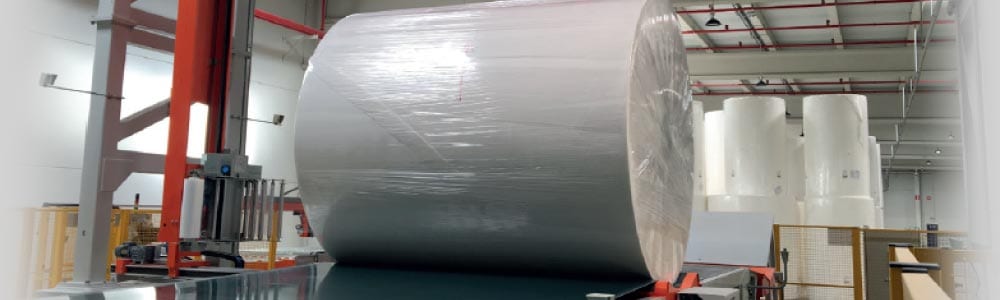

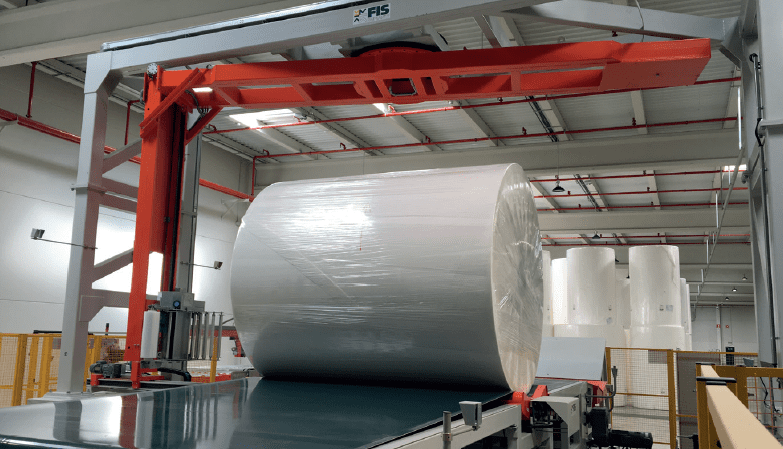

Today, the latest generation of tissue machines produce jumbo tissue rolls with diameters of up to 3m or more, weigh close to five tonnes and are often extremely soft.

Each jumbo tissue roll can have different destinations: to combine, to convert, to stock or to be sold out in the market. After production on the tissue machine, jumbo rolls are usually handled by a proper handling line and at the end are transported with clamp trucks or LGVs. For these operations, the wrapping with stretch film of the rolls grants a better protection of the roll itself, reducing contamination and damage.

Furthermore, even if it’s not intended for the jumbo rolls to be sold externally, they can be stored for days or even weeks in the warehouse before being converted. This means that the importance of a good stretch film protection on the jumbo rolls is critical to preserve the paper quality (in terms of humidity) and the properties avoiding contamination of external agents which is detrimental for a hygienic product. Being as jumbo tissue rolls produced by the tissue machine are often characterised

by extra softness, it’s important not to damage them during the wrapping operations: this can be achieved with a proper film dispenser equipped with pre-stretch device.

FIS’s new generation film pre-stretch creates an accurate film tensioning control wrap of roll, respecting its edges and releasing the proper film quantity with the correct film tensioning in the light of the angle between the plastic film direction and the paper roll axys. This functioning means that the roll edges shape is respected.

Thanks to the adjustable film pre-stretch ratio up to 400% of the new generation FIS pre-stretch and, using a proper 100% recyclable LLDPE film, it is also possible to reduce consumable material costs. The pre-stretch ratio can be varied through the FIS HMI without stopping the wrapping machine and, in addition with the patented jumbo film dispenser (for easier film replacement out of wrapping area) reducing wrapping line idle time and

operator intervention.

The innovative high technology of the fully automatic FIS Axial 93 and 96

wrappers (version with rotating arm and rotating table) designed for extra soft giants jumbo rolls up to 3m diameter, in addition to the film pre-stretch device is characterised of a special deformable belt conveyor on board that adjust itself into a circular shape that has more of diameter as the theoretical jumbo tissue roll diameter which is being wrapped. By doing so, the extra soft jumbo roll is gently put in rotation by means of a large contact surface reducing the applied pressure on the external paper layers, without suffering stresses on the outer surface and thus avoiding their damage.

The user-friendly operation of the FIS fully automatic wrapping line is completed with the new release FIS Teleservice App (for the remote production check of handled/ wrapped reels and of wrapper status in terms of working hours, scheduled maintenance and reported anomalies) allowing an easy control of the line even if not being used by highly specialised technicians.

Last but not least, the FIS compact concept wrapping line is conceived to minimise civil works required for installation and to reduce allocated space

for the line itself in order to permit the placement of the line directly in the tissue machine hall.

This article was written by Marco Cirigliano, sales and application engineer, FIS Impianti, for TWM.