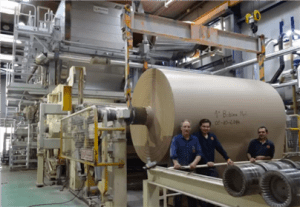

Spanish tissue producer LC Paper has started up its PM2 rebuild at its Besalu-based site after a major dry-end rebuild with Toscotec and sister company Milltech.

The rebuild project target was mainly to reduce PM2 energy costs and improve paper machine efficiency as well as increase the production at higher tissue grades thanks to the application of TT DOES (Drying Optimisation for Energy Saving) package.

LC Paper was formed in 1881 on the back of the Industrial Revolution and produces niche tissue products with PM2 and PM3, producing 65,000tpy of tissue for the AfH market.

Energy saving are an important aspect of the company’s business strategy and the company has been focused on cogeneration applications for several years, introducing a cogeneration plant at the site in 1993.

It was the first plant with a diesel engine of 6.5 MW in Spain that was expanded in 1999 with a second 6 MW engine.

The scope of supply featured a new double presses configuration with a rebuild of the felt run, a new TT SYD-15FT with doctoring system and a Duo-system Yankee hood, SMART eMT type from Milltech.

Maximum drying production with a machine trim width at reel of 3,050mm will be 130tpd.

With this new intervention the PM2 thermal consumption will be lowered to 1,350 kWh/t.