Spain’s ISMA 2000 S.L has signed up Toscotec and its sister company Milltech to deliver a major dry-end rebuild of PM1 at its La Torre de Claramunt site.

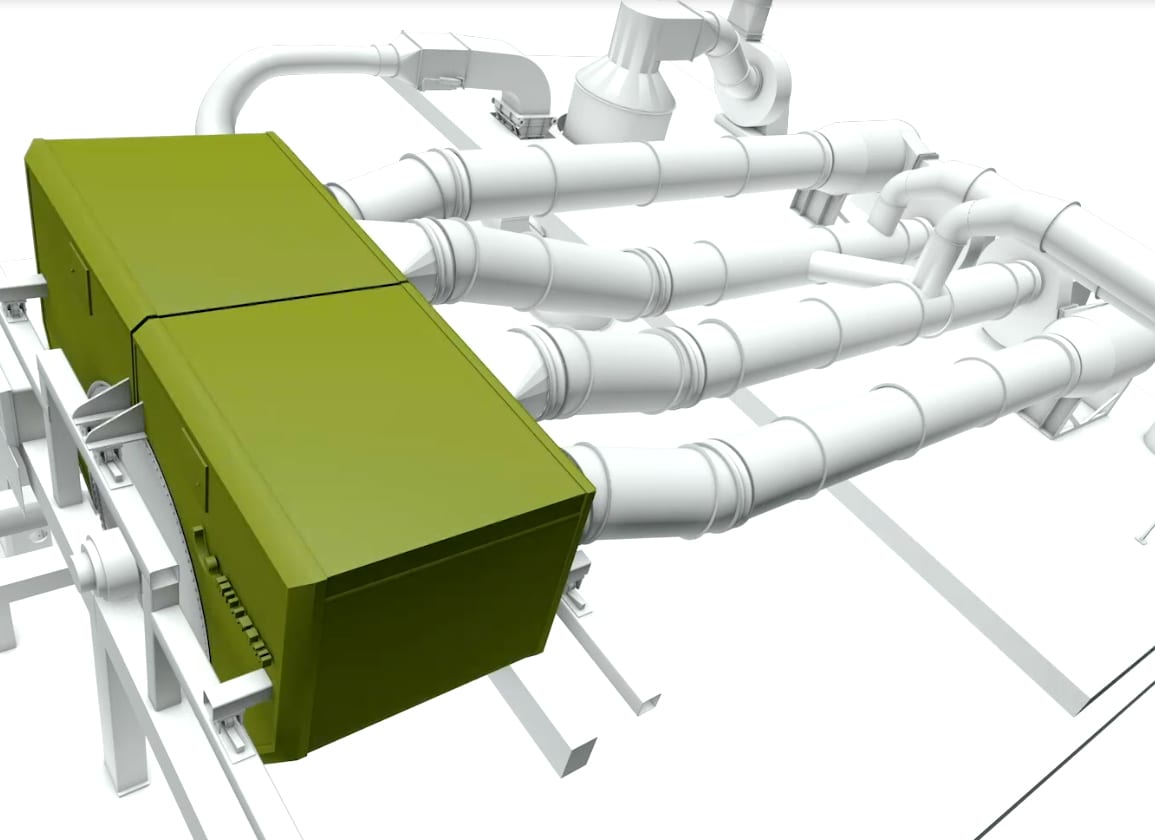

The start-up of the rebuilt machine is scheduled for the beginning of 2016 and delivery includes a major rebuild of the PM1 dry end section, which will be replaced with a TT DOES (Drying Optimisation for Energy Saving) package.

This will features a new TT SYD-3600MM provided with Toscotec-patented solution for head insulation, a new Yankee steam & condensate system and a Duo-system Yankee hood, SMART type, from Milltech.

The aim of the rebuild is to increase the production and performances of the Crescent Former machine up to 90tpd.

Fernando Luz, company general manager, said: “Our broad conclusion after a deep technical evaluation is that we are forced either to increase output for the same or less specific energy consumption input.

“This rebuild completes the one already initiated in the phase of pulp treatment allowing us to use complex raw material with high quality fibres and increasing efficiency and reducing energy consumption.”

ISMA 2000 SL has operation centres in Catalonia and the Balearic Islands.

The main business in Barcelona produces tissue products, while in Mallorca it collects and recovers waste paper.

Products are made from 100% recycled paper and include: AFH towel, kitchen rolls, sheets stretcher rolls, napkins, toilet paper.