By B&B – MAF’s technical sales manager Norbert Grothaus

The independent packaging machinery manufacturer talks to TWM about its latest innovation for end-of-line packaging products

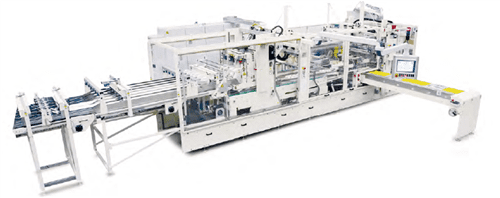

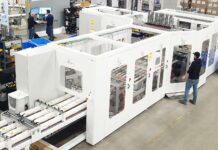

Among those one key focus is the development of baggers for toilet paper rolls, kitchen towels, facial tissues or folded paper towels and napkins. During the last few years we have increasingly concentrated on the optimisation of toilet paper roll baggers. The main goals for the advancement are to increase production to meet market demand and decrease down time from changeovers.

To reach these targets almost all components were improved and redesigned and this included:

- Re-engineering the infeed conveyor for controlled transfer to the roll turning and separating system

- No need for an additional buffer area in front of the machine

- Roll turning system with 90° swivel unit for faster change-over to horizontal orientated cores

- Fully equipped with servo drives to realise easy adaptation to all formats

- Bag opening units individually adjustable in width

- Format parts with attachment brackets for faster change-over

- “Easy-operating” system with visualisation – operator manual, circuit diagrams and spare part lists can be checked

- on the touch screen

- Easy access of the machine for cleaning and maintenance

Additionally the product range was extended with a lane diverter which can synchronise the in-feed and divide the products from four to three, four, five and six lanes. As a result we are now in a position to offer a complete solution for this market segment.

For the AfH and consumer market the so called bag filler BF 15 is based on the existing lines. The machine was extended by a compression device which is integrated into the proven electronic gear system. This lately developed innovative unit ensures a controlled, constant and tight package, as well as a gentile product handling experience.

Different in-feed systems allow an individual connection to the upstream machinery on customer’s request. The BF 15 is able to pack horizontal and vertical orientated products wrapped in paper or PE while speeds of up to 30 bags per minute can be achieved.

By using standard components a steady machine performance, high dynamic machine motion and short changeover times can occur. The long lasting experience in sealing systems guarantees perfect seams and a very long lifetime.

Depending on the format the optional extension of the wicket conveyor allows an operating time of almost one hour without having to add any bags.