Sofidel has started up a Valmet-supplied Advantage ReTurne energy recovery system at its Delicarta Valdottavo in Italy.

It is the first installation of Valmet’s new technology and aims at increasing energy efficiencies of tissue production lines.

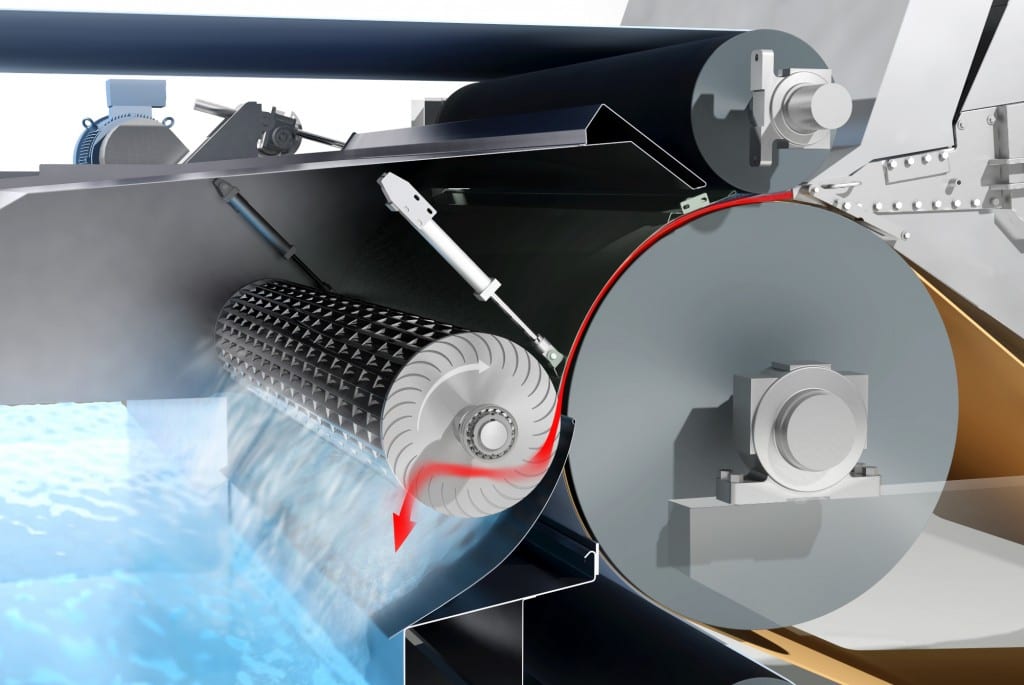

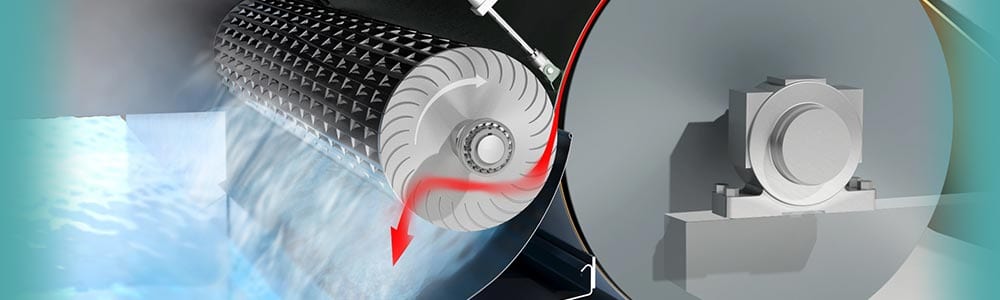

The system recovers energy from the headbox jet power and also returns it back to the process as electrical energy.

Simone Capuano, vice chief technical officer, Sofidel, said: “Its energy saving capabilities turned out to be better than we hoped for and well in line with our target to further reduce our CO2 emissions before the end of 2020.”

The Advantage ReTurne energy recovery system is installed in the forming section.

Valmet said it is unique in that sense that it recovers 50% of the energy from the headbox drainage water and via a generator converts it to electrical power which supplies the sectional drives.

“It does not affect the formation of the paper or the tissue making process, it is easy to handle and has low maintenance need,” the company added.